Restoring a small suv Pt. 1

The 1991 Geo Tracker Had a Major Mechanical Failure and Then Sat In Dirt and Mud Under a Tarp for Several Years. Let’s See If This Veteran Restorer Will Get the Little SUV Back On the Road Again.

Editor’s Note: This being the 30th Anniversary year for Auto Restorer, we decided to include some articles that hark back to what were the early days for the magazine and help to demonstrate the evolution of the hobby over the decades. In this case, we’re focused on Geo, a marque established by General Motors in 1989, the year that Auto Restorer got its start. Geo vehicles were built in joint venture plants with Japanese automakers or produced in Japan, and were sold by GM dealerships in an attempt to procure an increased share of the small-car market. This series will follow the restoration of a 1991 Geo Tracker, a small SUV built by GM and Suzuki, and sold by Chevrolet dealers. This may not be considered a standard restoration project vehicle but then the hobby never has stood still.

Automobiles come in many makes and models, and so do restoration projects. Our current project vehicle is a 1991 Geo Tracker 4-wheel drive mini-Sport Utility Vehicle. This project is a little off the beaten path, but has all the makings of an excellent restoration candidate. This SUV is a low-mileage truck that had been well cared for early in its life, but had since fallen on hard times. After suffering a catastrophic driveline failure, it spent the last several years stored under a tarp, where it degraded into pretty rough condition (Photo 1). There has been some debate whether vehicles from the 1980s and 1990s such as this one are good candidates for restoration, whether they are worth restoring, and how to deal with the challenges of all the computerized gizmos, emissions systems, plastic parts, and complexity (Photo 2). I believe that by the end of this project we will have a few answers to these questions.

The Project Picked the Restorer

For this particular restoration, I did not pick the project as much as it picked me. I had never seen the Tracker before its catastrophic breakdown, but had heard about it from a family friend whose son drove it to college on the other side of the state, about five hours away. It served reliably for several years, but started having drivability issues, plus the clutch was replaced due to slipping. One evening when the driver was pulling away from a stop sign, he heard a loud bang and a “spring breaking noise.” The engine revved to redline and the Tracker coasted to a stop; dead on the road. Something had completely let go between the engine and the drive wheels, and it would not move in any gear.

The truck was towed to a repair shop for an estimate, but obviously the shop could not give a definite estimate for the cost of repairs without a teardown to find the exact cause. The failure could be any number of things, from a bad clutch or cable to a broken transmission or any number of other maladies. The price range of repair costs was quite large, and was far more than a college student could afford. So the Tracker was towed home and left in the front yard at our family friend’s house. Shortly after it broke down I got a call asking for a guess of what the problem could be. Over the next few years, I saw the truck several times when I visited our friends. It was hard to tell exactly what the issue was, but it was obvious that the clutch was involved. The pedal had only half the normal travel and had an odd feeling to it. Other than that, it was impossible to know without disassembly. In the meanwhile, the truck sat in the yard, slowly sinking into the mud and deteriorating.

A Brief History of the Geo Tracker

Many people have heard of the Suzuki Samurai, but Suzuki Motors Corporation has had a long history building 4-wheel drive vehicles, starting with the introduction of the Light Jeep model LJ10 in 1968. These first-generation 4WD jeeps were known as the Suzuki Jimny and filled a unique market niche for a small off-road vehicle. Over the next decade Suzuki introduced a total of four models of the Jimny in a number of body configurations, including a hardtop, a convertible, and a small pickup truck. The first-generation Jimny was sold all over the world through late 1981.

The second generation of the Jimny was introduced in May 1981, and is the model that most people know as the Suzuki Samurai.

The Samurai was a very successful series of small 4x4s built and sold worldwide through 1998, and came equipped with a carbureted 1.3-liter engine. The Samurai has a reputation of being a fun, very rugged, serious, and reliable small off-road SUV, and was sold in the North American market from 1986 through 1995. The Samurai has a cult following, and there is a very enthusiastic and passionate community of owners of these trucks.

The Jimny line lives on in Japan and many other markets, but not in North America. In fact, a new 4th generation Jimny was just introduced in Japan in 2018.

After the Jimny Came the Sidekick/Tracker

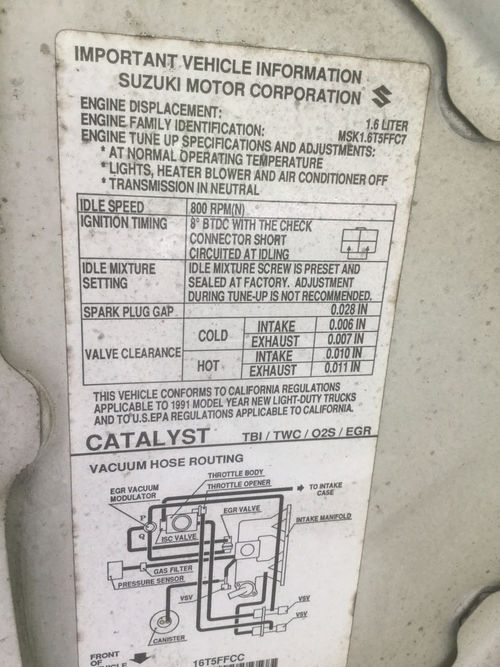

Our project truck is a Geo Tracker, which was also badged as a Suzuki Sidekick. The Tracker and Sidekick represented a new, updated and slightly larger line of Suzuki 4-wheel drive mini-SUVs. Introduced in 1988, it came equipped with a larger 1.6-liter fuel-injected engine and independent front suspension. It kept the rugged ladder frame of its predecessor, along with a dual-range 4-wheel drive transfer case.

The Trackers were sold in the United States by Chevrolet dealers as part of General Motors’ GEO (world) series of cars, and as the Sidekick in Suzuki dealerships.

They were also known in Canada as the Pontiac Sunrunner, GMC Tracker, and Chevrolet Tracker. In other parts of the world they were called the Escudo and Vitara. The numerous names can be very confusing, so for this series of articles we will refer to the project truck as a Tracker to keep things simple. This particular vehicle was built in Canada at CAMI Automotive, a joint venture manufacturing plant built by Suzuki and GM in 1986.

A Project Is Born

It was obvious that something needed to be done about the Tracker. My friends and I had occasionally talked about it, and eventually a plan emerged. I hate to see things being neglected and I was between projects. Our friends needed to de-clutter their front yard and to get the truck down the road, one way or another. A deal was made, and I started the long journey of bringing the Tracker back to life.

Mold, Mold, and More Mold

I had inspected the Tracker shortly after it broke down, and the body and interior were in reasonably good shape. But when I saw it again two years later, I was surprised to see how much it had deteriorated. As it sat, water had leaked inside and soaked the carpets, and mold had started to develop. The owners had cleaned up the interior and then covered the truck with a blue tarp to stop future water leaks. Unfortunately, the tarp also sealed in the moisture, creating a miniature rain forest. This created the perfect environment for mold to grow. In fact, the mold had completely taken over, growing on every interior surface, including metal and glass (Photos 3 and 4).

Combating the Mold

Mold is not only unsightly and smelly, but it can also be very dangerous. Mold is a living organism, and some species of mold are quite toxic. When you breathe in air infested with mold spores, they get into your lungs and can make you ill. Keeping this in mind, I did not enter the Tracker without taking a number of safety precautions beforehand.

The first thing was to remove the blue tarp to start drying out the interior. I started work on a very warm spring day by rolling down the windows and letting the truck air out for a few hours while I did other work. This allowed a lot of the loose mold spores to blow away with the wind and to start drying out the interior. Even standing downwind of the Tracker, the moldy smell was bad enough to raise a cough.

Next, I put on a face mask and latex gloves and started wiping down the surfaces with disinfectant cloths for those areas I could safely reach from the outside. There are several good brands of disinfecting wipes that kill mold and germs on contact. I used Clorox wipes, which we keep at home for cleaning the kitchen and bathrooms. The steering wheel, gear shifter, driver’s seat, and door panel were the first areas to be disinfected. For the first round of de-toxing the interior, I used an entire canister of disinfecting wipes on the driver’s seat and cockpit area alone, then another on passengers’ side. When I completed work for the day, I put a dehumidifier inside the interior to continue to remove moisture and lower the humidity below the point where mold can grow. If a dehumidifier had been installed when the Tracker was parked, the interior would have been in much better condition (Photos 5, 6 and 7).

The dehumidifier lived in the Tracker for several weeks to help dry out the interior. It is always shocking to see how much water a good dehumidifier can pull from the air. I drained off the water at least once a week, removing more than a quart of water every time for the first three weeks. At that point, I felt it was safe to enter the interior, but only while wearing a face mask to keep from breathing mold spores. I was not able to open the rear door due to a stuck latch, so the rear compartment could not be properly cleaned until I got it home to my workshop. Even with those precautions, I did pick up a cough that lasted for a few weeks. I think it was from a summer cold, but my wife believes it was from working on the Tracker. We will never know.

Fitting a Tow Bar

This Tracker, like many of its siblings, spent the early years of its life being “flat towed” (on its wheels) behind a Recreational Vehicle. When it served as the RV support vehicle, it had been fitted with a tow bar and frame mounts. The tow bar itself was long gone, but the mounts were still attached and in good condition. I purchased a new tow bar which I adapted to fit onto the existing mounts. This would allow towing the Tracker home behind my pickup truck, rather than hiring a tow truck or renting a tow dolly. This proved to be a good decision (Photo 8).

A No-Start Situation

During the two years that the Tracker sat, the battery drained and eventually went dead. Initially when the truck was parked the owners started it monthly to keep the battery charged, but after it was covered with the tarp it was not possible to run the engine.

I removed the battery and took it to my shop to see if it could be brought back to life on a trickle charger. However, it was too far gone to save, and given the age of the battery a new one was the way to go. In addition, the positive battery terminal had corroded in half while sitting, so a new battery terminal also was required. I installed the battery and did a “field repair” of the battery terminal by cutting away the damaged ring portion of the terminal, and bolting the undamaged portion to a new replacement battery terminal. (Photo 9).

With the power back on, I was able to check out the electrical system. The lights worked, which would allow me to tow with the parking lights on for safety. The turn signals and hazard lights worked properly too.

At that point I tried to start the engine, but with no success. It cranked over, but did not start. Despite coaxing, I could not get the engine to even whimper, let alone fire. It was very disappointing, but I did not need a running engine to tow it home. I elected to wait on further troubleshooting until it was back in my shop.

The last of the issues to be solved at that point was a fairly common problem with cars that sit for a period of time. One of the drum brakes had seized up, preventing the truck from rolling. This problem stopped all progress in its tracks, both literally and figuratively.

The emergency brake had been set during storage, so I was suspicious that one of the cables was stuck and did not want to release. A friend who has towed many VW buses with dragging brakes also gave me some pointers and several good ideas for how to deal with this problem.

I isolated which brake was stuck by dragging the Tracker backwards a few feet using my truck and a chain. I could see that three of the tires rotated, but the left rear tire dragged. Knowing which tire was the problem, I jacked up the rear and blocked it with jack stands, then removed the tire and set to work to break things free. I started with the emergency brake cable, pushing and pulling on the cable to try to coax the cable to slide inside the housing. Next I cracked the brake bleeder valve in case residual hydraulic pressure was holding the shoes out. Finally, I tapped on the brake drum to try to seat the shoes back to their stops and break up any surface rust. I tried a dead blow mallet, but did not have much luck. Eventually I moved up to my ball-peen

hammer, which broke the shoes loose enough to allow the brake drum to turn. The brake was still very tight, but moved enough to allow the tire to turn. At that point I was able to reinstall the wheel and tire and head for my shop (Photos 10 and 11).

The Journey Home

At that point, everything was ready to tow the Tracker back to my shop. First thing on a Saturday morning, I used my pickup truck and a tow chain to drag the little SUV backwards onto firm ground (Photo 12). After jockeying the vehicles into position, I installed the new tow bar and a set of safety chains and carefully towed it home behind my pickup. Even though the overall distance was only about six miles, I took it very slow and easy to make sure everything was safe.

I stopped after the first quarter mile to look at all the tow connections and to see if the dragging brake was overheating. The dragging brake was warm, but it was not hot to the touch so it was safe to continue. I stopped several more times, checking on the dragging brake to make sure it was OK. There were no problems, and before long I had the Tracker home to my shop (Photos 13 and 14).

I spent the rest of that afternoon thoroughly washing the outside, another round of cleaning the inside, and inspecting under the hood. Troubleshooting the engine start problem revealed a no-spark condition which turned out to be a much bigger deal than it first seemed.

So follow along next time while we dig into our Tracker project to get this little SUV back on the road again.