Are porcelain-coated manifolds a good idea?

Question:

I am in the process of restoring a 1937 Packard Super Eight and I want it to be right. The intake and exhaust manifolds were originally porcelain coated, but there is very little of it left, and the manifolds are rusty and pitted. Are there services that can restore them, and is it costly? Is the new JetHot ceramic coating a good alternative? Thanks for your help.

Answer:

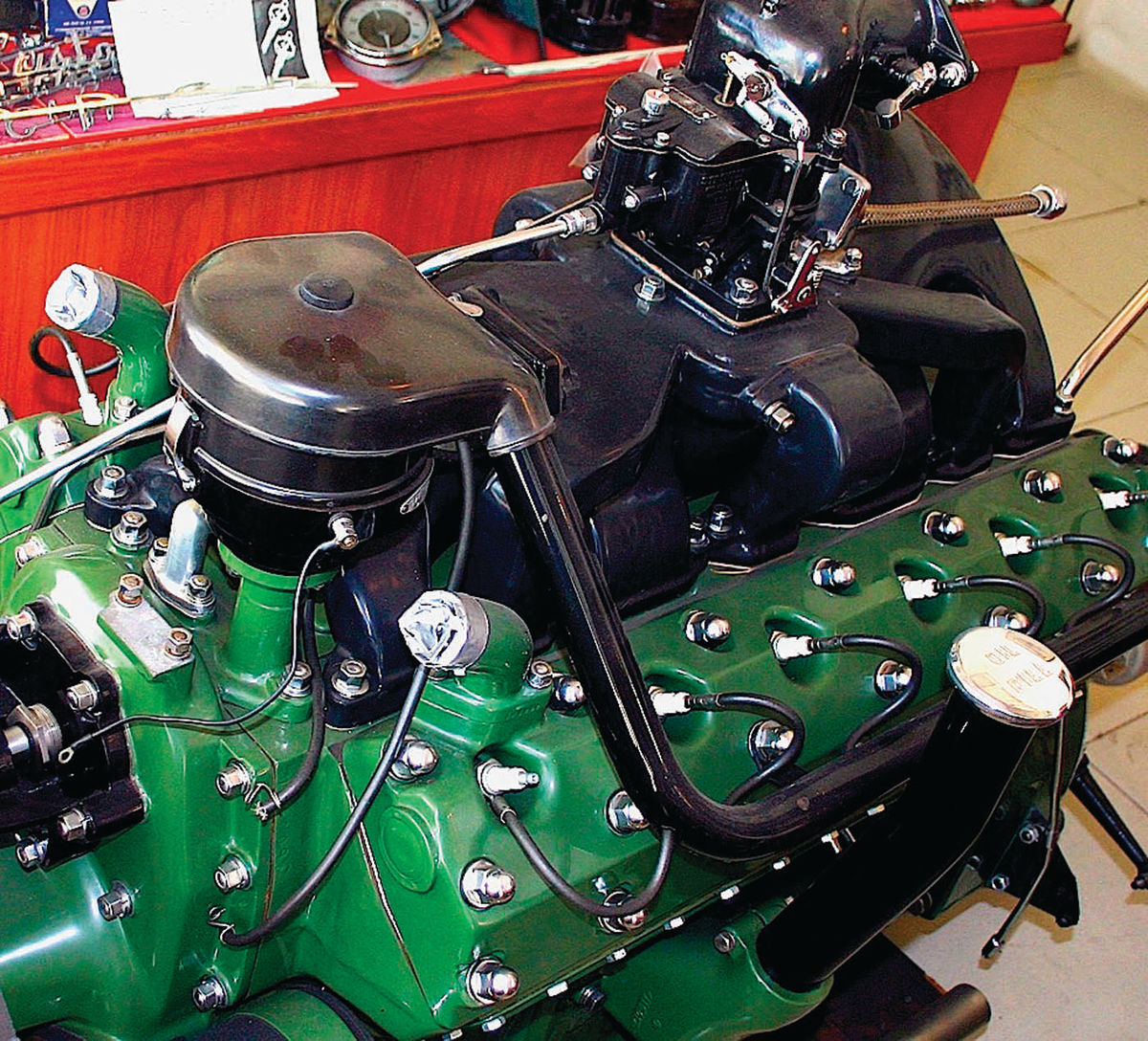

There is no doubt that porcelaincoated manifolds look great, and they were typical on many high-end cars of the 1930s where the engine was as detailed and finished as the rest of the car. Also, Packards International, the major club for Packard owners and fanciers, will deduct points at their shows if your engine’s manifolds are not porcelain-coated, if that is the way they came from the factory. However, the downside is the coating can be somewhat fragile and requires extra care in the areas of engine tuning and coolant management.

If water from the cooling system blows back onto the hot manifolds— especially the exhaust—the porcelain will shatter like the glass it in fact is. Also, if you make the mistake of running the engine too lean or the spark a bit retarded, the engine will run hot and crack the porcelain. And over time the continuous heating and cooling of the manifolds will cause cracks and make bits of porcelain flake off as well.

Another problem with having manifolds porcelain coated is that, after the manifolds are media blasted to get all the surviving porcelain and rust off of them, any cracks (and there most likely will be some) will need to be fixed before the coating process can begin. That means having them Magnafluxed to detect almost invisible hairline cracks and then welding up any cracks and filing them smooth before proceeding. To do the welding and porcelain work a pro with a furnace is required because the manifolds need to be heated uniformly.

If you do decide to go that way obviously you will need to remove the manifolds from the car. It is best to take them off as a unit along with the carburetor on an inline eight. Begin by disconnecting the battery to prevent sparks. Next, remove the air filter and set it aside. Now disconnect the carb linkage and the fuel line from the carb, then undo the exhaust pipe, and evenly loosen the nuts holding the manifolds in place a little at a time starting from the ends and working toward the middle.

Once you have the assembly on your bench, remove the carb and wrap it in plastic to keep dirt out. Next check to see if the heat riser flap in the exhaust manifold is free and that its spring is in good shape. If the flap is stuck open it will make the car hard to start on cold days because no exhaust heat will get to the intake manifold, and if the flap is stuck closed you will have problems with a lean mixture and vapor lock in hot weather due to excess heat.

To weld the cracks, the manifolds need to be heated in an oven evenly and gradually to orangey red before doing the repair. People occasionally attempt to weld or braze up cracks on exhaust manifolds without heating them, but the integrity of the cast iron around the weld will be damaged when you do that and most likely sooner or later the weld and the damaged metal around it will pop out. At that point you will need to find another manifold.

After the welds are done, the hot manifold will need to cool slowly and evenly over a period of hours before it can be removed from the furnace and cleaned up with files. Once the repairs are made, the manifolds can then be heated again and coated with porcelain at 1400 degrees Fahrenheit. And once again, there needs to be hours of cooldown time to prevent cracking before removing them from the oven.

Also, with all of this heating and cooling the manifolds may no longer be totally straight and true even though they were bolted to a metal bracket to prevent warping, assuming the job was done properly. And that means it is very likely their mating surfaces will have to be ground flat before installing them again.

If you do decide to have your manifolds redone with porcelain it is advisable to have them coated on the inside too. This will help insulate them and convey the hot exhaust gasses down the exhaust pipe. The exterior porcelain will last longer if you do this, and your engine may even make a bit more power.

But if you decide that porcelain isn’t worth the trouble and expense, a highperformance ceramic coating is a good substitute. It is a lot less expensive and more durable than porcelain, though the black coatings produce only a satin finish, and the pitting and casting marks on the manifolds will show to some extent because the coating is thinner. By the way, these new coatings are called ceramic, but the ceramic or metallic material in them produces essentially a high-temperature plastic coating, not porcelain.

Ordinary powder coating will not hold up because it becomes molten at 400 degrees, which is far below the temperatures to which exhaust manifolds are subjected.

Barring a ceramic coating, perhaps the easiest and cheapest way to keep your manifolds tidy is to occasionally shoot them with high-temp barbeque paint. Barbeque paint is available from hardware stores. This dries to a matt finish that at least looks better than rust.

If you want to go for original correct porcelain contact:

Commercial Enameling Co. 1310 East Borchard Ave. Santa Ana, CA 92705 | cecosinks.com

If a satin-finish ceramic coating is right for you, try: