My Electric Fuel Pump Just Helps to Start the Car

I HAVE FOLLOWED WITH interest the letters covering the use of an electric fuel pump to augment the mechanical fuel pump on carbureted classics. I too was disturbed by having both the electric and the mechanical pump running all the time the engine was on.

On my 1964 Rambler Typhoon with a 232 cid inline 6 and Motorola alternator, I connected a 12-volt relay across the no charge warning light. On the Rambler, the light bulb in the instrument cluster is wired in parallel with a resistor mounted near the voltage regulator. This circuit provides the initial bootstrap rotor current to energize the alternator. Once the voltage from the alternator stator reaches 12 volts, the light is extinguished by the fact that it has +12 volts on both terminals. The relay coil responds just like the light bulb. The relay contacts provide power to a rear-mounted electric fuel pump through a separate fused circuit from the battery. The resistance of the relay coil does increase the bootstrap current through the field coil in the rotor, but this seems to have no affect on the operation of the light or of the alternator.

On the Rambler, when I turn on the key I can hear the pump pulsing. Once the engine starts, the pump shuts off. Check the wiring diagram for your classic and see if you can hook this up as easily as I did. The relay that I used is one of the small 1-inch cube relays you can find at any auto parts store. You only need one with normally open (N/O) contacts.

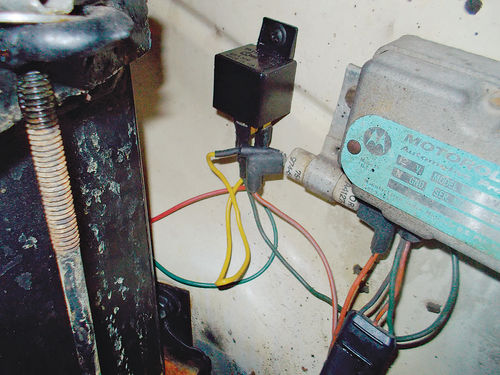

I’ve included photos of the fuel pump and the relay for the pump. In the photo of the relay, you can see the Motorola voltage regulator and just to the left, the resistor that parallels the no-charge lamp. The resistor increases the bootstrap rotor field current over the ¼-amp of the lamp. Plus it enables the alternator to function should the lamp burn out. To the left of the resistor is the small cube relay. I was able to piggyback the relay coil connections onto the ¼-inch push-on terminals of the resistor. (“No wiring was injured in the making of this movie.”) The relay (N/O) contacts take power from the battery positive terminal through a 5-amp fuse and connect to the fuel pump in the rear of the car near the fuel tank. The top photo is looking up at the fuel pump itself which I mounted on an aluminum bracket made from scrap, which is bolted to the Panhard arm body bracket.

Carl Bauske Charlottesville, Virginia.

Editor’s note: As you no doubt assumed, the car pictured on this page is Carl’s ’64 Rambler Typhoon, an uncommon vehicle from AMC. Introduced in April of 1964, the limited-production Typhoon was a specially trimmed Rambler Classic two-door hardtop that was created to draw attention to AMC’s newest engine of the day, the Torque Command 232 cid six-cylinder. The 232 was the largest-displacement six from any domestic automaker at the time and was rated at 145 horsepower and 215 lb.-ft. of torque. The Typhoon was equipped with bucket seats and a center console, and special black moldings were placed on the body sides. All Typhoons came in Solar Yellow paint with a black roof and only 2520 were produced. We’ve asked Carl for an article on his car and will feature it in the near future.