Engine Report: Early Four-Cvlinder Jeep engines

THE WILLYS-OVERLAND Model MC engine is a four-cylinder flathead design built by Willys and Ford Motor Co. for the Army 1/4-ton 4x4 utility truck, more commonly known as the Jeep. Prototypes were delivered to the Army in October/November of 1940 for evaluation, and regular production started at Ford with the Model GPW in November 1941 and with Willys’ MB in March 1942. In addition, the Willys MA was introduced in June 1941, but only 1505 were built. Ford produced 5756 pre-war GP models starting in February 1941.

All the various WWII-era models had the same four-banger flathead engine regardless of who built what. Only the die-hard Jeep enthusiasts would know that the Bantam Co. also entered a prototype in the Army competition. The Bantam Reconnaissance Car, 1175 Model BRC 40, was built starting in March 1941. Bantam was unable to fill the military contract, so it stopped production after building about 2700 units.

The Jeep engine is a robust and reliable power source. I know of one that has racked up more _ than 100,000 miles — all within the confines of a 400-acre farm. It’s been abused to the point where any self-respecting V-8 would have sued for damages long ago, but it still keeps running, and looks like it will outlast its body and frame.

The secret to reaching 100,000 plus miles on a Jeep engine is to maintain it properly and don’t ask it to do what it wasn’t designed to do.

Driving a four-cylinder on today’s roads is no problem as long as you realize top speed will be in the 45 to 50 mph bracket, providing the ground is flat. (The only time a stock WWII-vintage Jeep will exceed these speeds will be shortly after making a right turn off the middle of the Golden Gate Bridge.) Longevity won’t be a problem provided the revs are kept in a reasonable range and not above 4000 rpm for any length of time.

The people I spoke with at Archer Bros., a Jeep parts and repair shop in Hayward, California, said that if you start with a good block (no cracks), your grandkids will be the ones to worry about a second rebuild — probably when they’re your age. Archer Bros. is a good place to go for any Jeep parts, MB or GPW. I found more interesting bits and pieces after a one-hour prowl than I ever knew existed.

The Ford engine is slightly more rare than the Willys, and if you have a Ford-built chassis, be sure to get a Ford engine if you care about an authentic restoration. Part numbers are different between the Willys and Ford engines. Ford used “GPW” part numbers and Willys used “MB”. Some of the Ford bolts have an “F” script on the heads and are highly sought after by owners of Ford Jeeps. I’ve seen two quite wealthy collectors with grease up to their el bows, sorting through boxes of hardware looking for F-script bolts. When either one found what he was looking for, he’d raise it over his head and yell “Got one!” at the top of his voice. Most specific Willys bolts marked A, AA, EC, and TER are still available through parts shops.

Problems

The major problem to watch out for is overheating and the resultant possibility of a cracked block. If you’re buying the engine from a swap meet or other source, hang on to your money until the head has been pulled and the top of the block inspected. Look for cracks running from the valve pockets to the outside of the block and for cracks around the head stud holes and near the upper portion of the distributor side of the block. Cracks can be pinned and repaired by a competent machine shop, but because there were so many built there’s no reason to start from scratch with a poor block. Another area to watch is on the oil-strainer support pipe between the oil screen and the bottom of the block. The flange on the top of the support pipe is only secured with two cap screws and has a tendency to warp on the face when the bolts are tightened. (I do not mean overtightened.) Because this flange sits above oil level, air can be drawn into the pump. Air makes a particularly poor lubricant in an engine and will wear out bearings in a hurry. Face the flange flat on a piece of glass. Check for any air gap between the flange and glass. Correct the problem by using a file if you’re good at shaving level strokes, or have a shop smooth it off if it’s really got a curve to it. NOS replacements are available if you have no success getting yours flat.

Sometimes the starter has a hard time cranking the engine with the stock six-volt battery. A cure for this is to install an eight-volt battery with higher cranking power. No other changes have to be made to the electrical system. Eight-volt batteries can be ordered through parts houses or in the Yellow Pages under “Batteries, Automotive”. Don’t try this with a 12-volt battery. All the lights will easily take eight volts, but won’t take the additional four volts that a 12volt system supplies.

Another cause of poor starting is failure to attach all the grounding straps between the engine, frame and body. If the strap between the starter and the frame is not connected — or if there are dirty connections between the face of the strap and its attachment point — the mystery of why the engine won’t spin over rapidly will drive you around the bend. I count at least 12 bonding straps attached to everything from the transfer case/body strap to the generator/regulator strap used on the Fords only. The straps are particularly important if radios are installed, because they help eliminate ignition noise. All the parts on the Jeep are there for a purpose and need to be installed.

Driveabilty can be improved by changing the Carter WO carb (4539S) to a Solex single-barrel carb. Keep the Carter though, as the next owner might want originality over performance. With the stock carb, poor running can sometimes be traced to the throttle shaft. The shaft and bushings wear and air enters through the bushings, playing merry hell with the idle. The carb can be rebuilt, but I would estimate the cost at $175 to $225. I recommend the Solex at events and the Carter at shows

Over the years I’ve not had any problems running unleaded gas in any engine designed for leaded fuel, including some high-performance V-8s. The Jeep engine was designed to run on just about anything that will pour through a straw and burn, so octane ratings aren’t very important on a stock, low-compression engine. The gasoline of the ’40s had nowhere near the octane ratings found today. And because the Jeep was used in places where gas quality was even less than normal, the engine was designed with a 6.48:1 compression ratio ow in comparison to other vehicles of the era) to run on 60-octane fuel. (Most fuel at this time was about 73 octane.)

Oil Filter

The bypass-style oil filter — filtering some of the oil some of the time — is not a good design. Oil feed is taken from the number one main bearing, an area that needs all the oil it can get, then eventually gravity-fed back to the pan. A restored engine needs the filter for show accuracy, but it doesn’t have to work. I recommend blocking the filter inlet line and keeping the oil in the engine. Change the oil frequently — every 2000 miles or six months — and you won't have any problems.

Fuel Filter and Pump

Keep the fuel filter clean. It has a brass element that needs to see the light every six months whether the motor runs or not. If your Jeep’s engine doesn’t run often, drain the fuel filter before operation. There is a strainer drain plug located in the bottom of the filter. Loosen the plug and let it run until only gas flows. Normal maintenance is every 500 operating hours, or more often if conditions are severe or the engine remains idle for long periods of time.

The fuel pump is a bit of a problem when it comes to rebuilds. The NOS diaphragms are usually so brittle they crack after a few miles. Buy a new or rebuilt post-1984 fuel pump (these are readily accessible) and use the innards in the old body. Make sure the priming lever is in the down position. Replace the pump outlet check valve when the engine’s rebuilt. An inoperative check valve can cause the fuel pump to lose its prime, making the engine impossible to start.

Cylinder Heads and Blocks

Watch for sub-standard Ford engine blocks produced in 1944. Due to a casting change, some of the blocks aren’t as strong as others. Casting #K10-4 to L29-4 (November/December 1944) require special studs for installing the valve-spring cover assembly. Given a choice, I'd avoid these blocks. Not many survived as collectors items, so it’s not much of a problem, but still check the block casting number on the lower right side to be sure.

Those particular Ford blocks are more prone to cracking and are harder to find. Make sure you have a good one before starting a rebuild. Any head and block from either manufacturer should be magnafluxed for cracks.

More performance can be extracted from the engine without reliability suffering by going to a head with an 8.5 or 9.0 to 1 compression ratio. You can go all the places the big dogs run. Use gears and driving ability to climb mountains instead of horsepower.

Valve Train & Cam

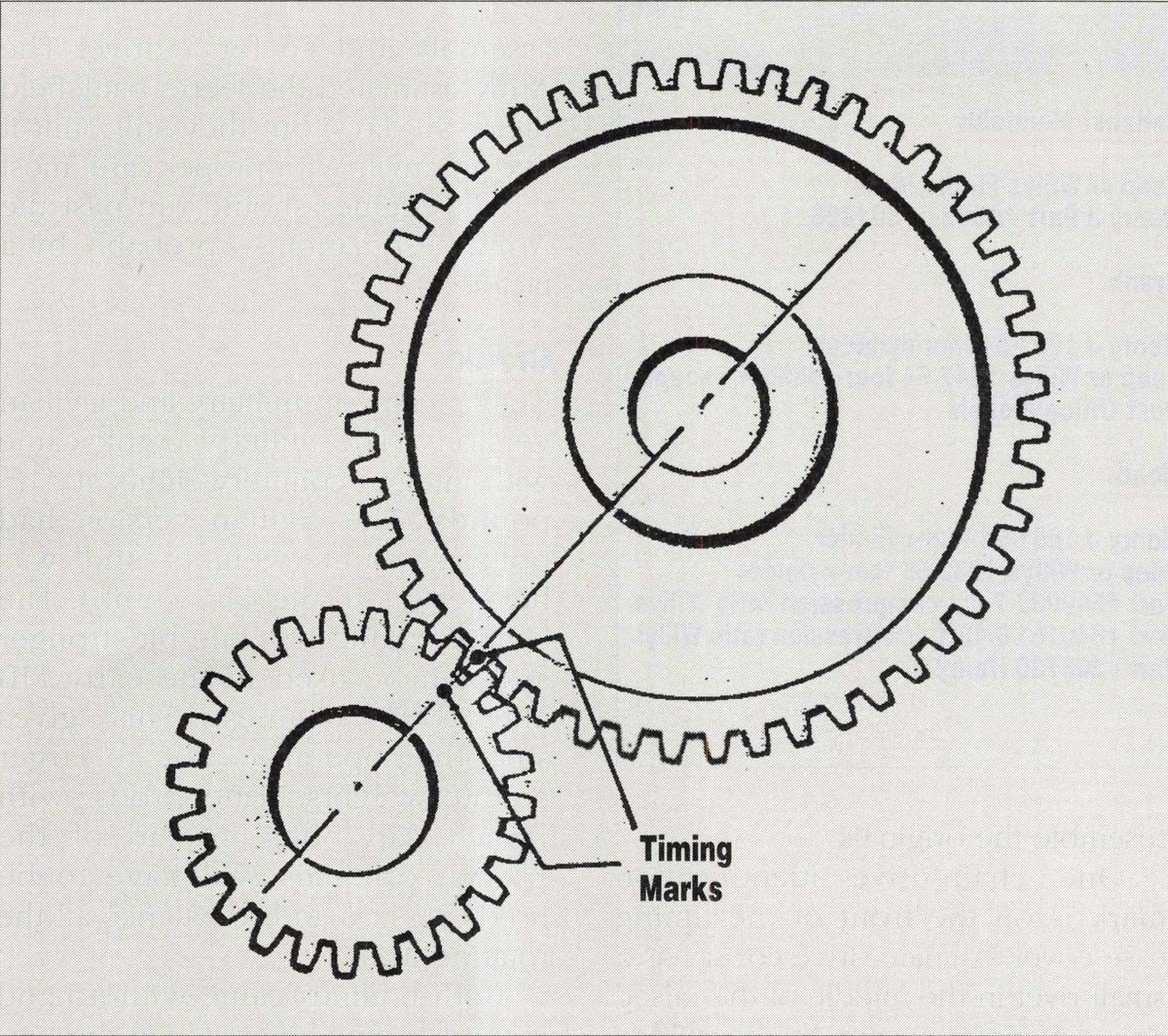

Early Ford and Willys engines had a chain-driven cam. After S/N 142370 chassis, the engines were changed to gear drive. This necessitated a different cam and oil pump because the gear drive turns them in the opposite direction than the chain drive. The gear drive is more reliable and a high-volume oil pump can be used with it. High-volume pumps made for Jeep CJ-5s (1967-on) bolt on and resemble the originals.

One chain-drive mark is on the front of the timing case cover. A chain-drive cover has a small rivet in the middle of the raised area covering the cam; the gear drive cover is smooth.

identification

Factory valve settings are .014inch, intake and exhaust. I recommend going to .016 intake and .018 on the exhaust strictly to take care of heat expansion. They will be a little loud, however, I'll take the noise over a burnt valve any day.

The cam rides in a single bearing at the front with the rest of the journals running steel-on-steel. Be sure and check the back three journals in the block to ensure they aren’t worn too badly. The front intermediate should be 2%-inch in diameter; the rear intermediate 2%-inch and the rear 1%-inch. Too much clearance and the block will have to be repaired (bushed).

Pistons & Rods

Pistons are aluminum alloy, T-slotted for expansion, cam ground, tin plated and strong. The drop-forged rods are fairly long — 9 % inches from center to center. They can be straightened if bent. New ones are inexpensive, though, and I recommend replacing the set when the engine’s opened. After all, they may have been there since 1945; they deserve a break. Use new rods and pistons; don’t overbore the cylinders past .060-inch (install new sleeves if necessary); use care in assembly and go for a drive. The Army estimated the Jeep’s battlefield life at 90 days, but they still built it like an anvil. With proper care, most rebuilt engines should run past the Army’s estimation — probably by a factor of 1000.

Crank

Cranks came in military and civilian versions. The military crank came with integral counterweights at 41.5 pounds. The civilian version had bolt-on counterweights and was heavier (as in the CJ-5 crank). The civilian crank is a little bit stronger and can be used in the early MB and GPW engines. This gives smoother operation due to larger counterweights. Later rods with %-inch cap bolts instead of the Y%e-inch originals will have to be used. Be sure and re-balance all the rotating mass.

Both engines came with a hand crank for those days when the battery just didn’t want to come out and play. (Hand crank part numbers are Willys #WO-A289 and_ Ford #GPW17036.) The hand crank fits through the grill, under the radiator, and over the crankshaft nut. Having cranked more than a few engines in my time, I can tell you spinning one is an acquired talent. Bring the engine just past a compression stroke and give the crank a good yarf. If all’s right in the engine, it will start right away. If it’s out of tune, your right arm will end up longer than your left. (You'll remember the kickback for a long time.)

Hand cranking works much easier on a stock, low-compression engine than a 9.0:1 motor. Theoretically, the motor end of the crank was tapered in such a way that when the engine caught the crank would back off — that’s theory. In practice, a goodly arm and no small amount of talent is very helpful. Better still, keep the battery well charged.