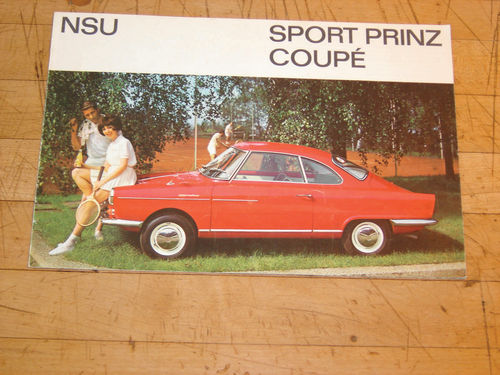

1959 NSU Prinz Sport

I Thought I’d Seen Them All… Until This One Came Along. The Project Won’t Be Easy, But I’m Hooked On My 1959 NSU Sport Prinz.

As both a classified ad junkie and a car guy, I’ve spent a lot of time scanning listings for interesting automobiles. I’m not necessarily looking to buy; I’m not a dealer. I just get intrigued by the stories behind the cars and the people who own them. Of course, now and then my resistance breaks down and I do end up with another project in my garage.

I tend to buy projects for two reasons. First, I like the doing of it— the challenge of getting something back to at least a functional, perhaps even beautiful, whole from a pile of parts. Second, I like to save things worth saving. Not every old car is. For me, they need to have something about them: some personal nostalgia, historical significance or novelty of design. That’s why I was brought up short when I spotted an ad for something called an “NSU Sport Prinz.”

NS Who?

Having grown up in the U.S. in the 1960s, I was immersed in car culture from an early age. Customs, antiques, sports cars—I love them all, both foreign and domestic. I’ve had my fair share and thought I’d heard of most of the rest, but I’d never heard the name NSU.

I learned that NSU was a German bicycle maker that had evolved to produce motorcycles and, in the post-WWII era, cars. In so doing, they adapted their motorcycle power plants. So their initial offerings were two-cylinder, inline, air-cooled and only 500-600cc displacement, typically yielding 20- 30 horsepower. As time went on, they and a number of other small auto makers in Germany were bought up by Volkswagen and eventually amalgamated into what is today Audi.

When I looked at the photos I was really intrigued. The owner was actually selling a pair of the cars. He apparently always bought his cars in twos—one to restore, the other to supply parts. The photo showed two dilapidated, humble-looking little cars that reminded me of Kaiser’s Henry J.

They had the same big-eyed, cartoon-mouse front-end, especially without the bumpers. They also had the same rear fins, part of the rocketinspired design fad of the 1950s and ’60s. And they had the high, bubbletop roofline that promised excellent visibility, while giving the overall shape a certain balance.

I thought I detected genetic connections with cars like the Alpha Romeos of the period. I later came to learn this was true…the car was designed by Franco Scaglione of Bertone in Italy, who also did designs for Alpha and others.

The owner was only willing to sell the cars as a pair, along with a whole pile of parts. I really didn’t have room for two more cars and was still in the midst of my current project. So I decided to show a little restraint for a change and pass.

And Now for Something Completely Different…

But the images haunted me. There was just something so unusual and appealing about the little cars that I couldn’t get them out of my mind. Doing a little research, my interest was piqued further when I learned about their novel air-cooled power plants. The cars were just refreshingly different from anything else I’d seen.

I’ve been fixing up cars and attending car shows for years. One of my proudest achievements had been finally completing my first nuts-andbolts restoration and actually attending as an entrant instead of a spectator. Most of the shows in my area center on big, old American cars, particularly muscle cars and hot rods. But, frankly, the redundancy started to wear on me after a while. After all, how many times can you get excited about row-after-row of the same models, the only distinction being the paint scheme?

So I started to branch out, going to higher-end gatherings, like Concours d’Elegance events where there was much more variety, especially worldwide entries. I grew particularly impressed with innovative post-war German engineering represented by odd little cars like the BMW Isetta and the Messerschmitt KR200. The “bubble car” category was filled with examples of how German engineers cleverly made use of what they had in a resource- and fuel-starved post-war Germany to create basic, functional transportation for the masses.

Yet, in all my travels, I had never seen an NSU Sport Prinz. The prospect of being able to attend one of these gatherings with something totally unique really took hold of me. So I called the seller back.

Unfortunately, someone had gotten there before me. A guy had driven up from Florida to make the purchase. However, he had only taken one (the better) of the cars and as many parts as he could fit on his trailer. The second car was still there, albeit missing its engine—the purchaser had gotten that, too. Still, I reasoned, if the car was salvageable, how hard could it be to piece it back together? Blissfully ignorant, I went to take a look.

A Mere Shell of its Former Self

It was, in essence, just a shell. Yet while the body had a fair amount of dents, dings and rot, it seemed structurally sound. All the glass was there and intact. The dashboard was there and still contained most of the instruments. The door handles, locks and window cranks were still in place and working. The suspension was there; at least enough to mount some junkyard wheels/tires and roll it around. But that was about it.

The other buyer had not only removed the engine/transmission unit, but had done so in a hurry. Control cables, rods and wiring had been cut through. There was no interior, save for one rusty seat frame. There were no bumpers, headlights or taillights.

Still, the owner was going to give me a couple of partial engine/ transmission units that he thought might be combined to form one working whole. He also had a bag of other miscellaneous stuff he’d throw in as well, plus he’d deliver the whole thing to my house for me. He priced it low enough that I figured even if I gave up on it I could get my money back, at least in parts. I’d been able to do that once before with an old Nash Metropolitan that turned out to be beyond salvage.

So I took it.

Approaching the Project with Caution

Now, I’m not totally naïve. I had an idea of what I was in for. Aside from locating all the missing parts, I know from experience that the most expensive part of any restoration is usually the sheet metal and paint work. I learned that the hard way with my first restoration. It was an old U.S. Army Jeep that came my way. I did everything myself mechanically, but the extensive body repairs were beyond my ability at the time so I had to farm it out to a pro. Months and many thousands of dollars later, I had a vehicle that was probably worth about a third of what I’d put into it. I vowed I’d never do that again.

So on my next project, a VW van, I went in determined to do at least the body repairs, if not the paint, myself. I’d acquired a little more welding skill and a MIG welder by then and was actually able to do a pretty nice job of it. I took on the NSU with the same plan.

However, before I invested a lot of time and effort into the body, I wanted to find out just how hard it was going to be to line up the missing componentry. Here, I was in for a surprise.

Scouring all the usual sources turned up virtually nothing in the U.S. I learned that a very limited number of these cars were ever brought over from Europe and those that did had long ago succumbed to the rust worm, fed by our heavy use of road salt on slippery winter roads. I located one car in Oregon that had literally broken in half when its current salvage yard owner unloaded it from the trailer. There was very little left usable on it and what there was the owner seemed unwilling to bother stripping and shipping.

This was a common problem I ran into. When I would chance upon someone who had a car or parts they’d invariably show enthusiasm for selling at first, only to fade away when I tried to pursue them. I’m not sure whether it’s part of the hoarder’s mentality not to want to part with things or whether they found the parts unusable after they dug them out of their basements.

At any rate, it was time to expand my scope. Hunts on-line located some parts in Cyprus, Israel, South America, the UK and, of all places, Ireland. It turns out NSU had once had a factory in Ireland, so many people there grew up with NSUs and there remains a devoted following to the little cars. Still, it was clear this was going to be a tough slog. So I reverted to Plan C.

I thought, with the body work on hold and now the parts hunt in a stall as well, I’d take a look at the engine/transmission units I’d gotten to see if I had any hope of putting together a working powertrain. If that fundamental challenge couldn’t be met, there’d be little point in going on with this difficult project.

Horsepower of a Different Color

When I pulled out the two units that had come with the car, my hopes seemed dashed. They’d both apparently been sitting outside in the mud for a while. One had a cylinder head, but the pistons were frozen. The other had no head; it had no cylinders or pistons; in fact, it had no connecting rods, at least not the tops of them. This motor must have been seized up as well, so someone took off the head, rotated the crankshaft enough to raise the cylinders off the case, then reached in with a torch and cut through the rods. I cringed just looking at it.

So I turned my attention back to the first engine with a determination to free the pistons from the cylinders. I needed to break the engine down, but wasn’t going to resort to the barbarism inflicted on the other engine by cutting the rods. In fact, I was hoping I might be able to re-use the pistons, rods and cylinders as I had no others.

So I removed the cylinder head and bombarded the bores with every penetrating oil concoction known to man, inventing a few more along the way. I tried heat, I tried hydraulic pressure, I tried everything. …Nothing worked.

Then, after weeks and months of soaking and applying torque in opposite directions and gently pounding on the piston crowns with a wooden mallet I got my first tiny movement! That was all I needed. I fell into a rhythm of dousing with penetrant, applying torque in one direction while pounding down on the pistons and lifting up on the cylinders, then repeating in the other direction. After many cycles, I was at last able to extract the pistons from the bores.

Breaking down the rest of the unit involved creating a number of homemade pullers and presses, but I eventually had it all apart. I now understood why it had been so frozen. Not only had the pistons seized in the cylinder bores, but the counterweight on the crankshaft had been effectively welded to an internal piece of the aluminum case that had somehow cracked and become deformed, possibly when water in the case had frozen and expanded.

I guess I shouldn’t have been surprised. The internals were about as black and filthy as any engine I’ve ever seen. Worse, generations of mice had actually nested inside the crankcase amidst all the grease and grime, literally filling it with seeds, pits, nesting materials and their own waste.

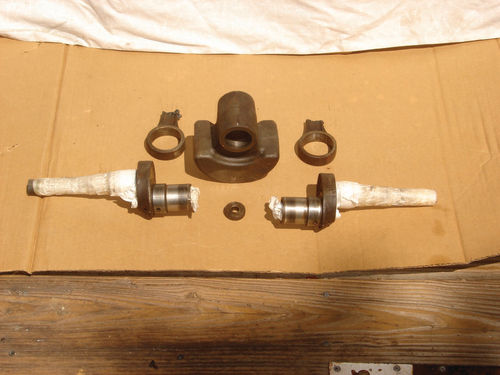

One of the connecting rods felt very loose on the crankshaft and showed signs of excessive heating at that end, so it was clear the rods had to come off, the crankshaft journals had to be inspected and new bearings would need to be fitted. This is where I encountered my next surprise. Unlike all the other engines I’d worked on, this had a multi-piece crankshaft and the connecting rods had no end caps. The lower connecting rod bearings were pressed into the rods, the rods were fitted to the crankshaft journals and then the crankshaft was pressed together.

So disassembly had to follow the reverse process, which meant somehow pulling or pressing apart the crankshaft. The problem was that, with the rods installed, there were very few ways to grip or support the halves of the crankshaft to force the pieces apart. I figured I’d deal with that later. But first, I needed a press.

Turning to a Press Pro

As I’ve said, to me the fun of an old car restoration is in the doing of it. You learn things, you find satisfaction in overcoming challenges and, at the end, you take pride in having completed it. Anyone with a big enough checkbook can go out and buy a car that’s already restored. Or they can simply farm out all the restoration work to others. Or they can buy every fancy tool and gadget to help them if they actually want to do some of the work themselves. Part of the challenge for me is figuring out ways to make do with what you have. Sometimes this means jury-rigging or knocking together what my brother and I came to facetiously call “spaceage tools.”

In this case, not having a press, I set out to make one. Thanks to the Internet, there are lots of homemade examples out there to emulate. I already had the key component— an eight-and-one-half ton hydraulic bottle jack—and I had a welder, so I scrounged up the steel and put one together. It was pretty respectable when finished, but it was only a buildup to the real show: trying to press that crankshaft apart.

It took a while, and many bent pieces of steel, but I finally found a way to support the crankshaft in the press, so I started pumping. But, like everything else so far, it wouldn’t budge. I knew I had hit a wall when the whole frame of the press (which was made of quarter-inch-thick steel channel iron) started to twist and rack. While I like to do things myself, I also bow to the wisdom of Clint Eastwood’s “Dirty Harry” character who said: “A man’s just got to know his limitations.”

So I took the crankshaft to an automotive machine shop. My damaged pride was somewhat soothed when the machinist told me it took a full 15 tons of pressure to separate the crankshaft. The journals of the crankshaft actually looked good, even the one supporting the worn rod bearing. However, not having full manuals or specifications on the engine prevented me from verifying that it would still be within tolerances to ensure adequate clearance and, therefore, oil pressure if I were to install standard bearings. In fact, the only manuals I have are partly in English, partly in German, limiting their use for even the areas they do cover.

The Sum of Its Parts

A breakdown of the other engine with the cut-off connecting rods revealed the same level of grime and mouse habitation as the first, though there were no breaks in this engine case. So, between the two engines, I had:

• Two usable case halves

• Two crankshafts, neither of which was confirmed in-spec

• Two connecting rods

• Two pistons that appeared to be usable, albeit needing new rings at a minimum

• A cylinder assembly

• One complete cylinder head, with pieces to a second

• An intake manifold

• A non-standard, but usable, exhaust manifold/muffler

• Pieces of a DynaStarter Still missing were:

• A carburetor

• Complete flywheel/clutch assembly

• All engine tin ware

• Remaining pieces of the DynaStarter

• Correct exhaust manifold/muffler Of course, I would still also need a full gasket and seal set, as well as replacement bearings and rings.

Further inspection of the engine internals, however, revealed still more vexing issues.

Many of the steel gears and other components had been heavily corroded by moisture and mouse droppings. After cleaning, some showed severe pitting—deep enough to have penetrated the hardening on the surface and, therefore, rendering them unfit for use.

In short, I had a pile of parts insufficient to really even think about reassembling a good, usable powertrain.

A Strange Twist of Automotive Fate

Ironically, an old foe came to the rescue. The buyer who had purchased the other car and cannibalized mine contacted me. He had finished assembling his and was interested in selling all the parts he had left over.

Unfortunately, he was about 1200 miles away from me in Florida.

But fortuitously, my brother was in the process of moving to Florida and just happened to be about to return north with an empty truck. So the pile of parts ended up coming all the way back home to Connecticut.

It turned out to be a windfall. It was a mix of good and bad, but the most important piece was one complete engine assembly. It, too, was billed as being frozen, though the other buyer said he had started to loosen it up. With persistence, I was able to completely free this engine, though the question remained as to its internal condition and whether maybe—just maybe—it might even run.

It Started!

I am fortunate to have a neighbor who is a mechanical genius. Not only does he teach automotive technology, he is an old farm boy, raised to fix anything and everything. His specialty is Ford Model Ts, but he takes great pride in—and is sought out by old car owners all over the country for—his ability to get anything running again. In fact, he delights in surprising people by breathing life into the most abysmal machines. He is also an eternal optimist and insatiably curious. I knew he’d be fascinated by this unusual power plant and the challenges it presented. Lucky for me, he was.

We lubricated the cylinders and rotated the engine by hand to ensure we wouldn’t be starting it dry and to ensure the valve train seemed to be operating properly.

We flushed the crankcase as best we could and refilled it with oil, again rotating the engine by hand to prime the bearings with oil.

We then tested the DynaStarter, a novel feature that combines a starter, generator and distributor all in one unit. It actually worked, so we used it to prime the engine further.

We cleaned and adjusted the points, found some plugs that would fit and made sure they were getting a spark.

All this was done with the engine sitting on a cart. To actually fire it up, we needed a test bed with coils and wiring. The obvious choice: the car itself.

As with everything else, the car’s wiring had been hacked to pieces by mice and men, but we were able to sort it out and we did have a pair of coils. Missing some pieces to the engine mounts, we had to devise substitutes, but we finally had the engine in, with intake and exhaust manifolds installed and wiring connected.

Now, what to do about fuel?

There was a tank in the car, but it was horribly gummed up. We had a shell of a carburetor, with some missing innards. We had fuel pumps, but they weren’t mounted and couldn’t be trusted at this point anyway.

So we drew straws to see which one of us would simply stand over the engine and squirt a bit of gas from an old oil can into the carburetor—not an enviable job, given the lack of air cleaner and unsure engine timing. But at this point, a flame out of the carburetor would actually be a sign of encouragement, even if it did cost us some hair on our knuckles.

After a few failed attempts and a lot of starter fluid, the engine actually fired up! We kept run time to a minimum, since we had no gauge to ensure oil pressure or ducting to provide adequate air cooling. But at least I now knew that I had the basis for a workable power plant, even if it has to be rebuilt. My plan is still to build up a complete new unit, but this gives me confidence enough to invest more time, effort and money in restoring the body and locating missing parts.

The Mystery of Its History

One way or another, I want to see this little car plying the roads again, even though, at 6’2” and over 200 lbs., I’m not sure I’ll even be able to fit in it. However, the aftermarket sunroof might allow me to stick my head out and at least take it for a spin. In fact, that sunroof offers the potential for still other interesting findings about this German car.

Among the many layers of paint, it seems the car was originally white but then received a professional bright yellow paint job at some point. So this was one of very few NSU Sport Prinzes in the U.S., made more distinctive by its yellow paint and non-standard aftermarket sunroof.

Interestingly enough, just such a car was used in the 1964 Rock Hudson/ Paula Prentiss movie called “Man’s Favorite Sport?” Could this actually be that car?

The film was shot 3000 miles away in San Francisco, but who knows? There’s probably no way to find out and it wouldn’t really add anything to the value of the car anyway. But, as with so many other cars I see in the classified ads, I’d just love to know the story behind it: how it ended up here in such deplorable shape, potentially all the way from San Francisco.

But that will have to wait. Right now, parts take priority over provenance…

Editor’s note: We’ve asked Bill to keep us posted as his project moves forward.