Electric Fuel Pumps and Modern Gasoline...

Some Pumps Can’t Work With Today’s Gasoline Blends. Here’s a Pump That Offers a Solution.

Based on the phone calls I receive on a daily basis, a lot of you reading this are having trouble with modern gasoline damaging your electric fuel pumps. The old Stewart Warner electric fuel pumps that we all used for close to 30 years no longer work with modern gasoline. The alcohol in modern gasoline causes the diaphragm inside the electric fuel pump to swell and tear, which in turn causes the oncereliable SW electric fuel pump to fail. Incidentally, this is what happens to the original OEM mechanical fuel pumps as well.

I experienced this first-hand with Great Race cars nearly 25 years ago. (In that event vintage vehicles are driven 3000 miles in two weeks’ time.) The Great Race teams were experiencing constant electric fuel pump failures. So I went looking for a solution. After doing some research I figured out that I needed to find an electric fuel pump that would pump alcohol and all types of fuel additives. (Remember this was back in the gasohol days...)

Alcohol’s the Culprit

If you have read my book, “The Official Guide to Modern Gas & Oil for Antique Vehicles,” I tell you to stay away from the alcohol/gasoline mixtures but depending on where you live that may not always be an option. If you are a Great Race entrant you do not have time to shop for gasoline, you buy it at the closest gas station next to the hotel or somewhere along the race route. You have to buy what is available and hope for the best.

You need to know that most all of the electric pumps that “chatter” and make noise, are diaphragm pumps, and the alcohol in modern gasoline will attack the rubber diaphragm inside the electric pump causing it to swell and tear. That is clearly what happened to the old Stewart Warner electric fuel pumps.

I also learned that the rotary vane pumps (which often make a whirring sound) are not reliable either as the modern alcohol fuel is a drier fuel with no lubrication properties, which causes the wafers inside of the rotary vane pump to literally grind themselves to pieces...much like when you crumbled your graham crackers in kindergarten.

To add to the problem, when a rotary vane pump fails, the wafer filings end up in the fuel filter (you do have one...right?) or worst case, under the needle and seat in the carburetor or plugging up the main jet in the carburetor. None of this is a good thing!

My Solution to the Fuel pump Problem

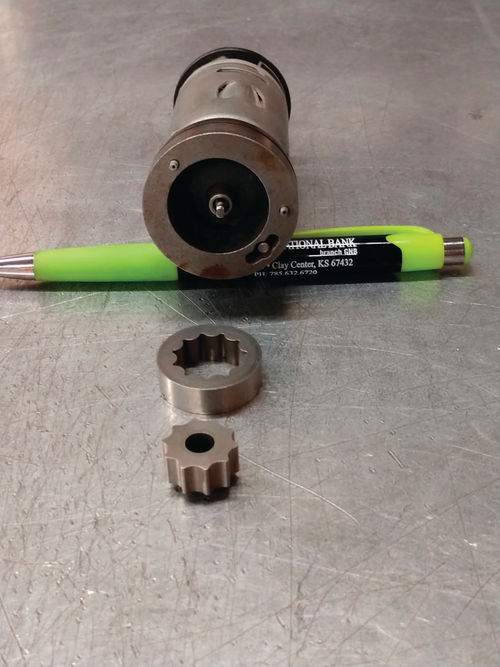

The technology that I have found works the best is a gear-to-gear design with two stainless gears inside the fuel pump. That setup works much like the oil pump inside of an engine. This also is how modern electric fuel pumps work while living inside of the gas tank.

I knew I was on the right track because the technology was proven. The problem was, none of the modern design electric fuel pumps were built for 6-volt applications, and the working pressure of the modern electric fuel pumps was higher than the 2-4 pounds that most antique vehicles require. So after six more months of R&D I came up with the solution.

The Fifth Avenue gear-driven electric fuel pumps are the same working pressure as your mechanical fuel pump, (2-4 pounds), so no fuel pressure regulator is needed for most applications.

They will work with both positiveand negative-ground electrical systems and they come with a 30-micron fuel filter installed. You will get a list of replacement fuel filter numbers with the pump so you can buy replacements locally. Also included are the mounting bracket and hardware.

Best of all, you can change the fuel filter without any tools. That was a feature the Great Race teams wanted so when they got into some “bad” gasoline they could change the filter in a hurry and get back on the road.

Pumps for 6- and 12-Volt Systems

I have the electric fuel pumps for both 6-volt and 12-volt applications. If you are into the technical numbers, the 6-volt pump has a peak output of 2 pounds of fuel pump pressure and delivers 15 gallons an hour which will easily take care of any single or multicarb application.

The12-volt version has a peak output of 4 pounds of fuel pump pressure and delivers 30 gallons of fuel an hour. Both pumps have a pressure check valve inside so they will shut off when your fuel line is full.

Since these pumps work like the oil pump inside of your engine they are quiet and can be used on any antique vehicle including, cars, trucks, tractors, boats, forklifts…you get the idea.

A Note Concerning Modern Gasoline…

Today’s modern gasoline has a lower boiling point (to help with emissions) than the gasoline in the old days. That does not affect the modern fuelinjected cars because they typically have between 40 and 100 pounds of fuel pump pressure. But it does affect our antique vehicles that typically have between 2 and 4 pounds of fuel pump pressure.

In addition, as noted above the modern fuel is dryer due in part to the alcohol additive, which will cause the gaskets in the carburetor to shrink, and then the carburetor to begin leaking. The first instinct usually is to go get a large manly screwdriver and tighten the screws in the top of the carburetor using manly force. That either strips out the screws in the carburetor or warps the housing, neither of which is a good plan. So be careful, and take the time to figure out the real issue involved.

Also, be careful when buying NOS carburetor kits on places like eBay. Most contain the old school Neoprene gaskets that are not made for modern alcohol gasoline so you will be right back where you started within a few months.

There is a chapter in my gasoline book that explains the modern gasket materials (Viton) and the other things you need to watch for. Also, do not use Teflon tape on your gas line fittings; the alcohol will dissolve the Teflon tape little by little with the pieces plugging up your fuel filter until enough tape is gone for you to have a leak…along with a plugged fuel filter.

Some Help for Vapor Lock

This brings us to the vapor lock problem that’s often found with our antique vehicles. Because modern gasoline does have a lower boiling point (for emissions) as compared to the gasoline of the old days, one trick is to add a pint of diesel fuel to 10 gallons of gasoline. The diesel fuel does two things: First, it raises the boiling point of modern gasoline, which helps with the vapor lock problem. Second, it lubricates the gaskets in the carburetor to keep them soft and keeps them from shrinking.

In an upcoming article I will get into more of the fuel and oil issues, but for now I wanted to focus on the electric fuel pump, why they often fail and a replacement pump that works.

When I’m done with this first series of articles you will have learned enough to make your antique vehicle more reliable and fun to drive. You will have the confidence to drive it and enjoy it instead of having it parked in the garage with a collection of garden tools leaning against it.

Regarding My Book and Fuel Pumps

If you want to learn more about using modern gasoline and oil in your vintage ride, my Official Guide to Modern Gas & Oil for Antique Vehicles is $15 and includes free postage for Auto Restorer readers.

My Fifth Avenue Electric Fuel Pumps come with a 2-year warranty and are available for $95 each. They are the same electric fuel pumps I install on the vehicles entered in the Great Race.

Getting In Touch With My Shop

To order electric fuel pumps, use the part numbers below:

6-volt - 92415EFP6…6-volt electric fuel pump

12-volt - 92415EFP12…12-volt electric fuel pump

My contact information is:

Fifth Avenue Antique Auto Parts

415 Court, Clay Center, KS 67432

Visit fifthaveinternetgarage.com,

or fax .

Editor’s note: Randy Rundle has been preparing cars for the Great Race since 1989. Randy and his Fifth Avenue Antique Auto Parts store sponsor a 1915 Hudson in the Great Race each year. Randy’s team won the Great Race in 1993, 2011 and in 2015.