Should you convert your 6 volt system to 12 volt? There are other options to consider as well.

PART OF THE FUN of owning an antique car is driving it. However, some of the same problems that plagued these cars when they were new are still with us. One common complaint is the six-volt electrical system. It is often blamed for the yellowish, dim headlights, dead batteries, and hard starting.

While it’s true a lot of vintage cars do have these problems, is it really the fault of the six-volt system? Will changing the system to 12-volt fix the problem? What about going half way and using an eight-volt battery? Will that help? How do you figure out what works, and what is best for your Car?

To find the best solution, we need to define the problem. This may come as a surprise to some, but an investigation into the workings of the six-volt electrical system will show the actual problem is not the six volts, but rather the lack of it. The six-volt electrical systems were designed so the system would function properly if a minimum of six volts is present throughout the system.

If only 5 to 5.5 volts are present at the battery post, which is quite common with the six-volt generator charging system, the problem is a shortage of electrical current. This explains why your taillight is dim. The reduced voltage, plus electrical friction (resistance) created as the current travels through the 10 feet of wire to the back of the car, makes it easy to understand how the power at the taillight socket could be as low as four volts.

Why does this happen? In part, because of how and when a generator charging system produces electrical energy. In most systems, the generator has little output when a vehicle travels slower than 20 mph (known as the generator cut-in speed). So the energy needed to run the ignition and lights is drawn from the battery. When the vehicle speed reaches about 20 mph (or the engine is running at an equivalent speed while the vehicle is motionless), the generator begins to produce electrical current, which recharges the battery.

The generator is designed to produce its maximum output at approximately 45 mph vehicle speed. From 45 mph up to 60 mph, the generator is operating at peak production. When a vehicle is traveling at speeds in excess of 60 mph, the output of the generator will begin to drop as the centrifugal force lifts the generator brushes off of the armature.

This is why larger (diameter) drive pulleys are used on generators as compared to modern alternators. The larger pulley keeps the generator working at an efficient number of revolutions per minute. It also keeps the generator rpms in check, making sure the generator doesn’t spin too fast. So in theory, the generator is the most capable of putting out its maximum capacity at highway speeds between 45 mph and 60 mph or about 4000 rpms.

At first glance, the simple solution to low-speed charging would be a smaller diameter drive pulley on the generator so it would spin the armature faster and produce more current at slower speeds. While this might work for town driving (Ut was used on in-town delivery trucks.), on the open highway the generator is likely to literally fly apart.

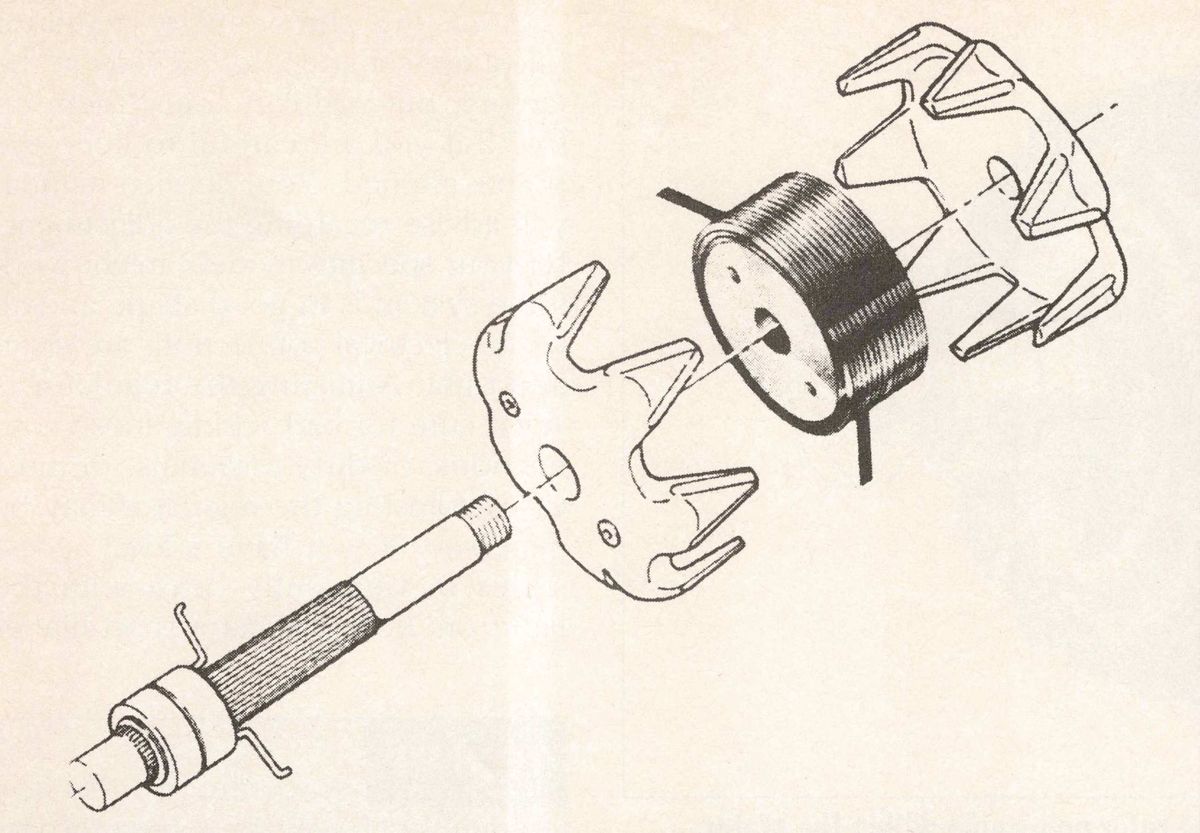

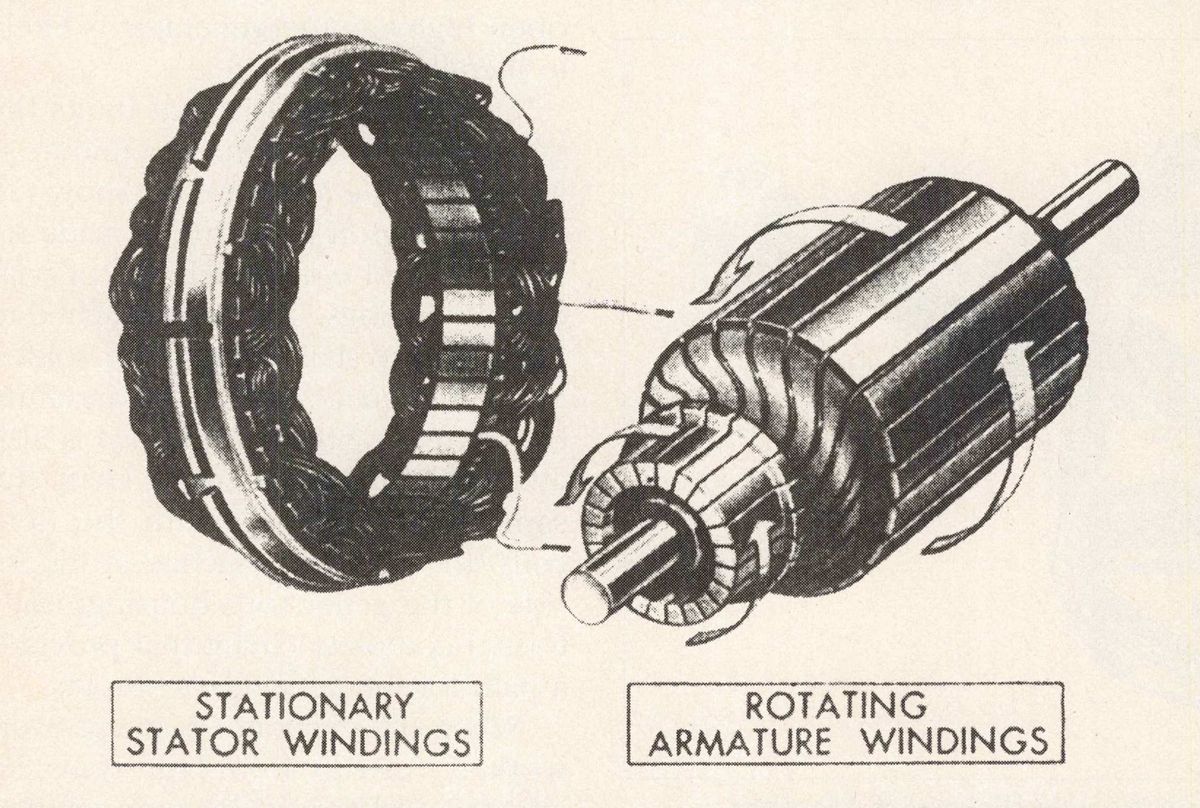

One of the factors that limits the generator’s revolutions per minute is its design. The armature (as shown in the drawing on page 20), is made up of a series of electrical loops of wire called windings. They are attached to the armature shaft using silver solder. The commutator end of the armature (the part the brushes ride on) is also attached to the armature shaft the same way. Together with the field coils (the magnets attached to the inside of the generator’s housing), they form a complete circuit that provides a path for the generator’s output.

When the generator is being overworked, (usually from high rpms, an excessive electrical load or a failed voltage regulator), excess heat is created and trapped inside of the generator. This heat builds up and softens the soldier that holds the components to the armature shaft. Finally between the excess heat and the centrifugal force, the armature windings and segments part company from the armature shaft. This ruins the armature and in most cases damages the field coils that are attached to the inside of the generator case. This was commonly known in the old days as “throwing the solder” out of the generator.

By installing an eight-volt battery the problem could be fixed, but only temporarily. This strategy is actually treating the symptom and will not solve the problem, the lack of six volts. A system that is unable to fully charge a six-volt battery will not keep an eight-volt battery fully charged. The eight-volt battery will require a minimum of nine volts from the generator. An eight-volt battery (when it is fully charged) will also stress the gauges and electrical accessories that were designed for a voltage range of between six and eight volts.

What about those 6/12 batteries? Will one help?

The design of this unit typically consists of two smaller 6-volt batteries in the same case. Twelve volts is provided to the starter using a Ford-type starter solenoid mounted on top of the battery. The solenoid connects the two batteries for starting purposes. While this is better than the eight volt battery solution, it also avoids the actual problem, maintaining a minimum of six volts in all of the circuits all of the time.

In the old days it was common to seek refuge from the six-volt system by replacing it with a 12-volt system. When the voltage is doubled, the required amperage is reduced by half. In the example we have been using, it would help because our total amperage load would be less. However, if a 12-volt generator is part of the equipment, it is likely the same low voltage problem will be experienced.

Adjusting the voltage regulator (Most are set at 6.2 to 6.5 volts at the factory, but you can adjust them up to 7.2 if you are careful to keep the points aligned. Your service manual will advise regarding the adjustments for your specifics model.) might work if the system is in good shape and all of the electrical connections are clean and tight. Adjusting the regulator is not a cure for bad wiring, loose connections, or dirty terminals. In most cases adjusting the regulator may be necessary if you have added accessories or frequently drive with the lights on. If the regulator is set higher than 7.5 volts, expect water to disappear from the battery and possible problems down the road as the generator struggles to maintain the additional voltage. When the setting exceeds eight volts, shorter bulb life is typically one of the setbacks.

When a 12-volt system replaces a six-volt system it involves items such as the dash bulbs, headlights and taillight bulbs; the ignition coil and battery; the voltage regulator and generator. The heater motor should be replaced with a 12-volt model for best results, and the original radio should be converted to 12 volts.

There is a product called a Runtz voltage drop that protects dash gauges when upgrading the electrical system to 12 volts. The gas gauge in particular is very sensitive and must have accurate voltage to the gauge in order to give correct readings. The Runtz voltage drop will also protect electrical water temperature gauges as well as oil pressure gauges. Ceramic voltage drops are commonly purchased, but they have a 40 percent error rate, causing inaccurate dash-gauge readings, and sometimes allowing excessive voltage to destroy the gauge itself. A voltage drop reduces voltage and is installed inline to the gauge or accessory. The ceramic voltage drops are about the size of a quarter with 2 terminals on the back. It gets hot because it is creating electrical friction or resistance. The Runtz won’t get hot because it is transistorized, not mechanical. Not only is the ceramic drop inefficient, the heat it causes could start a fire.

Generator or Alternator?

Alternators replaced generators beginning in the early 1960s. They soon were being retrofitted to the older cars that were being upgraded to 12 volts. One major improvement was the increased output the alternator provided while the engine idled or was at low rpms. An alternator can easily provide a 60 amp output at highway speeds, and maintain a 30 amp output at idle and slow speeds. In contrast the generator had little or no output at idle and a maximum output of 40 amps. The alternator not only improved output, it increased reliability.

In the early 1970s the alternator was again improved through the use of transistorized technology. The voltage regulator was reduced in size and placed inside of the alternator housing itself. Solid-state technology provided increased reliability and a simple compact charging system that required little or no maintenance for 80,000 miles.

What is the physical difference in construction that makes an alternator better?

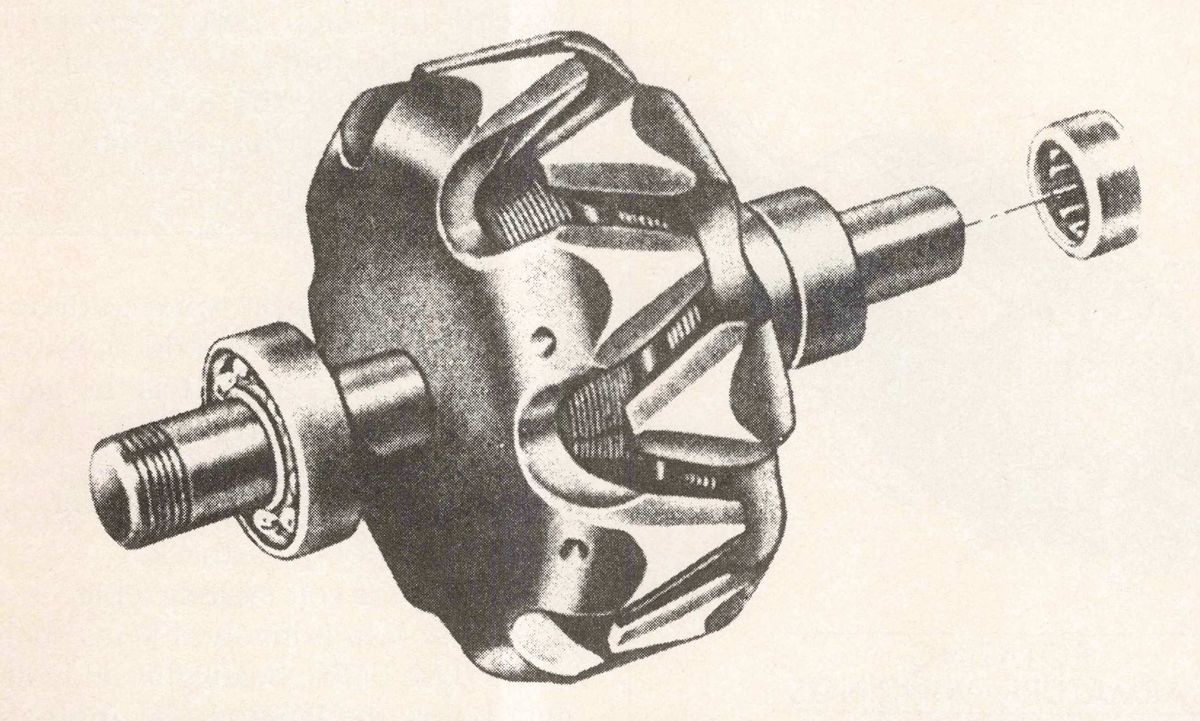

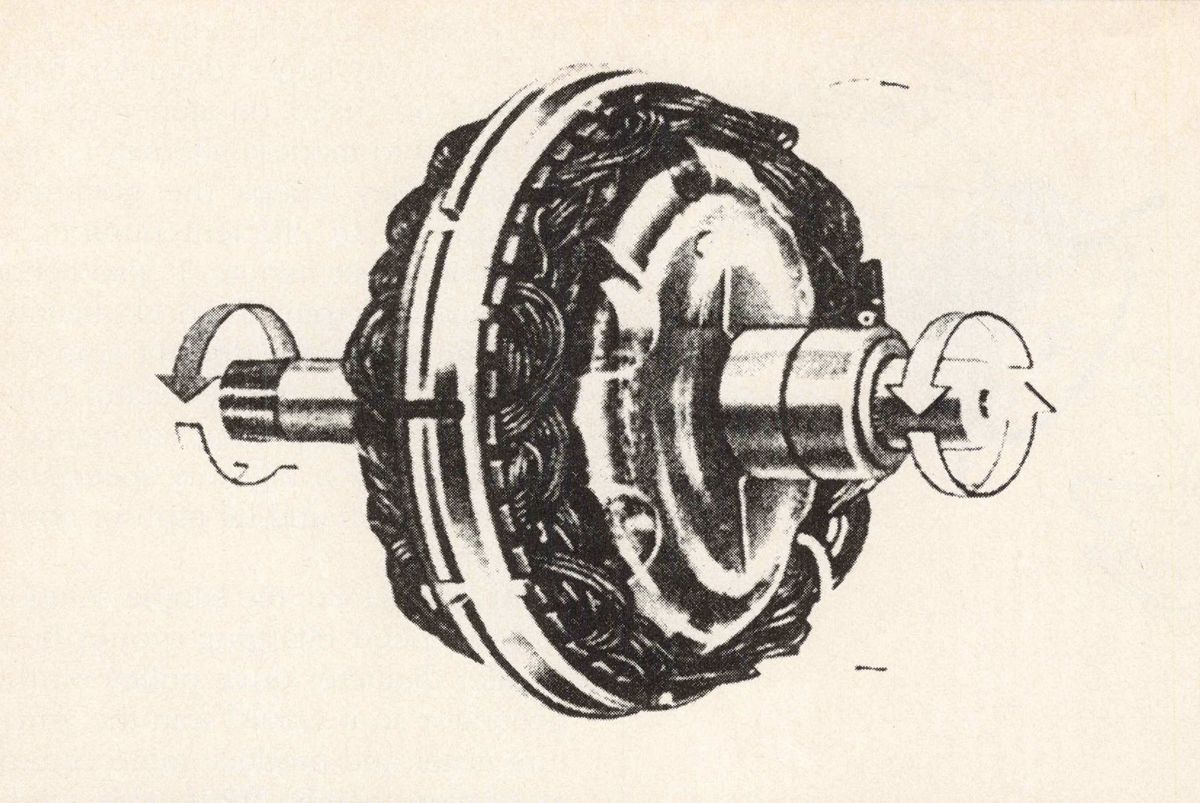

The alternator uses one large field coil that is attached to the rotor shaft. This means the field coil will spin along with the rotor shaft. In contrast the field coils in a generator are attached to the housing of the generator and are stationery.

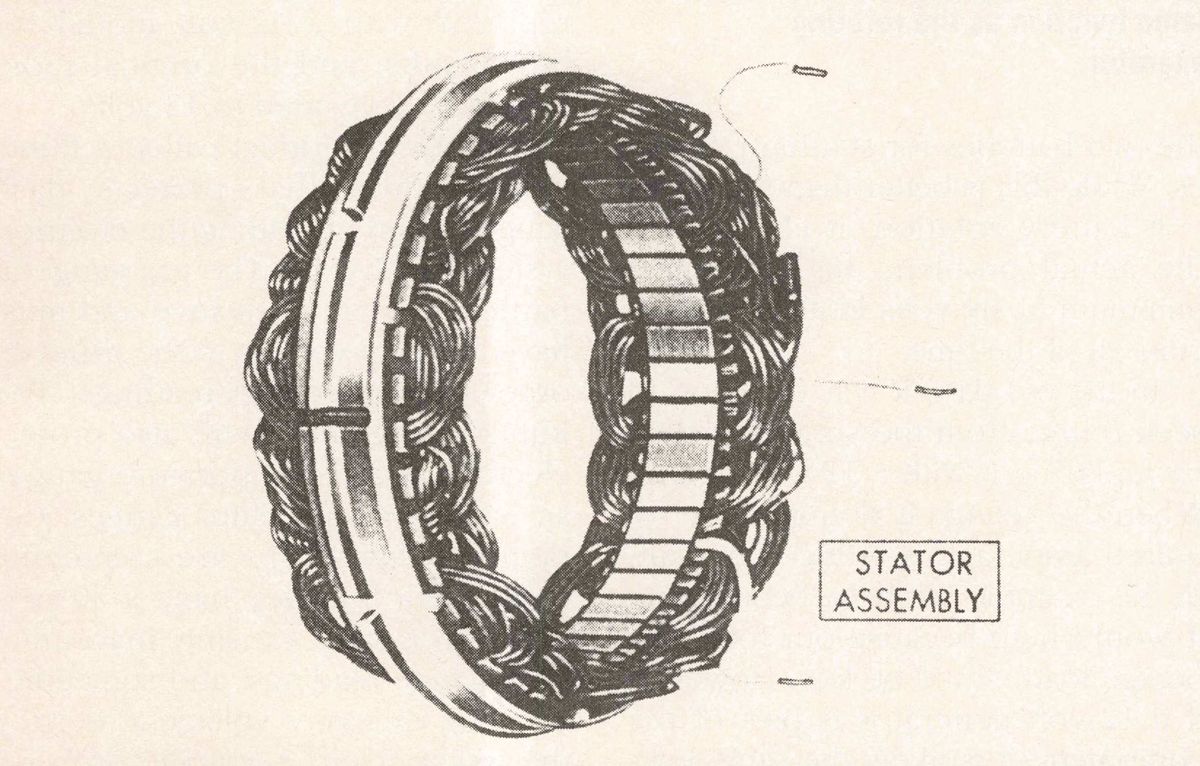

Inside an alternator the stator assembly is stationary and field coils rotate. Therefore it won't fly apart at high speeds like the old generators. The alternator also uses sealed bearings rather than bushings, which results in longer life and less maintenance since generator bushings need servicing every 3000 miles. Overall, there are fewer moving parts in a generator and a greater degree of efficiency.

The stator (stationary wire) windings in an alternator are attached to the stator frame and carry output current. They perform the same job as the segments on the armature of the generator.

The brushes in an alternator are connected in series with the field coil, and carry a low voltage only. The small amount of current is used to start the magnetizing process that is necessary to the functioning of electrical generation. The high voltage (output current) from an alternator goes through the diodes and is converted from AC to DC before going on to the battery. In contrast the brushes in a generator carry the total output from the generator. The low current carried by the alternator brushes greatly extend the life of the brushes as compared to those in a generator.

The regulator used on the early alternators was much like those used on generators. However, the external regulators soon became solid state. This eliminated many of the problems inherent to all regulators: sensitivity to outdoor temperature change and susceptibility to arcing of the points. The result was a more reliable charging system.

Additional benefits of the alternator included a reduction in size and weight. Typically a 60-amp alternator will weigh about 11 pounds. In contrast, a 40-amp generator will weigh about 20 pounds. The alternator is about half the length of the generator and only about one-third larger in diameter.

Alternator rotor-shaft speeds up to 12,000 rpms can occur before the alternator suffers. This allows alternators to be driven faster via a smaller diameter drive pulley, which results in greater output at idle and slow speeds. Most modern alternators are driven at 1.5 times the engine speed.

If, for instance, a modern high performance engine has a redline of 7000 rpms, and the alternator is driven at the normal 1.5 times engine speed, then the rotor shaft speed would be 10,500 rpms. That’s no problem for an alternator with a 12,000-rpm limit.

In terms of maintenance, alternators are typically trouble-free for as many as 80,000 miles, while a generator usually requires servicing at least every 10,000 miles. The job of repairing an alternator is much easier. There is no armature to undercut (a resurfacing procedure) and no commutator grooves to clean. In addition the alternator is assembled using sealed bearings as opposed to a generator’s brass or copper bushings that require regular oiling.

Next month: We'll talk about different types of alternators, including a 6-volt model, and give you some tips on how to replace your generator with an alternator.