Diagnosing and repairing malfunctions in vacuum-powered windshield wiper systems.

VACUUM-POWERED windshield wiper systems were introduced in the mid’20s, remained in widespread use until the late 50s and were installed on some vehicles into the 1970s. They worked well when the vehicles were relatively new, but decades later, many of these systems work poorly or fail to work at all.

This article will cover the fundamental principles that govern how vacuum-powered windshield wiper systems work and will discuss the diagnostic and repair procedures that will help you put your system in proper working condition.

How the System Works

The typical vacuum-powered windshield wiper system includes a vacuum motor, a switch and cable that actuate the motor, a vacuum pump that is an integral part of the fuel pump, hoses or lines that route vacuum to the motor, the wiper arms and blades, and the mechanism that transmits the motor action to the wiper arms.

When the wiper switch is pulled or twisted to the “on” position, the cable connecting the switch to the motor is retracted. This opens a valve on the wiper motor that permits vacuum to be applied to it.

The wiper motor is primarily powered by the engine’s manifold vacuum and the auxiliary vacuum pump’s purpose is to supplement manifold vacuum when necessary. This permits the wipers to function at a uniform rate even when manifold vacuum drops because of hard acceleration or high-speed operation of the engine. Some systems do not use a vacuum pump and are connected directly to the intake manifold or carburetor. Without a pump, it’s normal for the 5 wipers to slow down or stop when a the engine is under load such as when the car is accelerating hard or traveling uphill.

If the system is in proper working order, the wipers should operate between 80 and 100 strokes per minute on a wet windshield. And if the car is equipped with an auxiliary pump, this rate should be maintained throughout all ranges of engine load and speed. Unfortunately, it is quite common for vintage vacuum wiper systems to perform sluggishly or to quit completely. If your car’s system is not functioning properly, follow the diagnostic and repair procedures outlined in this article to return your wipers to their proper working order.

When Wipers Won’t Work

A complete wiper failure can be due to several factors. Begin your diagnosis by checking the supply of vacuum to the wiper motor. This is the easiest to diagnose and therefore a good place to begin. Disconnect the vacuum-supply hose to the wiper motor and connect the hose to a vacuum gauge.

With the engine idling, the gauge should have a vacuum reading of at least 14 to 16 inches of Mercury (Hg). If the gauge reads less than about 6 or 7 inches (Hg), the lack of vacuum is preventing the motor from working. Follow the vacuum-supply hose to its source, which is a port in the intake manifold or the vacuum pump. Use your gauge to measure the vacuum at the port to eliminate the possibility that an obstruction or leak in the line caused the low reading at the wiper motor. If the reading at the port is adequate, repair or replace the vacuum-supply hose.

If the reading at the vacuum pump port is low, the problem is in the pump and/or in the engine. In addition to the pump port that directs vacuum to the wiper motor, the pump has another port that receives vacuum from the engine. Disconnect the line that routes the engine manifold vacuum to the pump. Install your vacuum gauge on the line and measure the engine’s manifold vacuum. At idle, the vacuum reading here should be about 16 to 22 inches (Hg). If the vacuum is below 9 or 10 inches (Hg), you should eliminate the possibility of an obstruction or leak in the line by measuring vacuum at the source, which will be a port in the intake manifold or carburetor. If you obtain an adequate vacuum reading at the intake manifold or carburetor port, the problem is in the line. If you get a poor reading at the port, there is a problem inside the engine.

If the vacuum pressure entering the pump at idle is strong but the vacuum exiting the pump at idle is weak, there is a malfunction inside the pump. The pump’s inlet and/or exhaust valve is defective or the body of the pump is leaking. Disassembly and inspection of the vacuum pump should reveal the problem inside the pump.

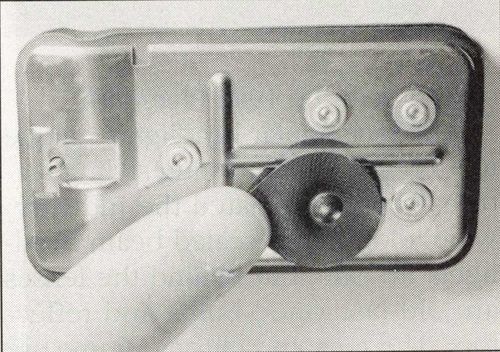

If the vacuum supply to the wiper motor is sufficient but the wipers still don’t operate, the problem is either in the wiper switch, the wiper transmission, or the motor. The switch and its cable are usually one assembly and the switch either pushes and pulls or rotates. Either way, the action of the switch should be transmitted to retract or extend the cable that connects the switch to the motor. Have someone actuate the switch back and forth while you watch the end of the cable where it connects to the slide on the motor. If the cable doesn’t move or moves very little, there is a problem in the switch and/or in the cable. Problems in these parts can usually be fixed by cleaning them with a solvent, blowing out the solvent with compressed air and lubricating with light oil. Sometimes the switch or cable is broken and you will have to locate a replacement to solve the problem.

Even if the cable does move the slide on the wiper motor, it may not be moving it enough to activate the motor. The slide is actually part of the valve that directs the flow of vacuum, which powers the motor. Disconnect the cable and move the slide through its range of motion by hand with the engine running. If the wipers go on and function properly, the cable is not moving the slide far enough. Try adjusting the cable where it attaches to the slide. This is accomplished by loosening a tension screw. Sometimes the cable is adjusted so it starts the wipers, but it won’t retract far enough to shut them off. If you encounter this problem, it means the range of motion of the cable is inadequate. Repair the switch and cable to obtain greater range of motion. Basically this is a clean and lubricate job. If you find broken or damaged parts that cannot be repaired, replace them.

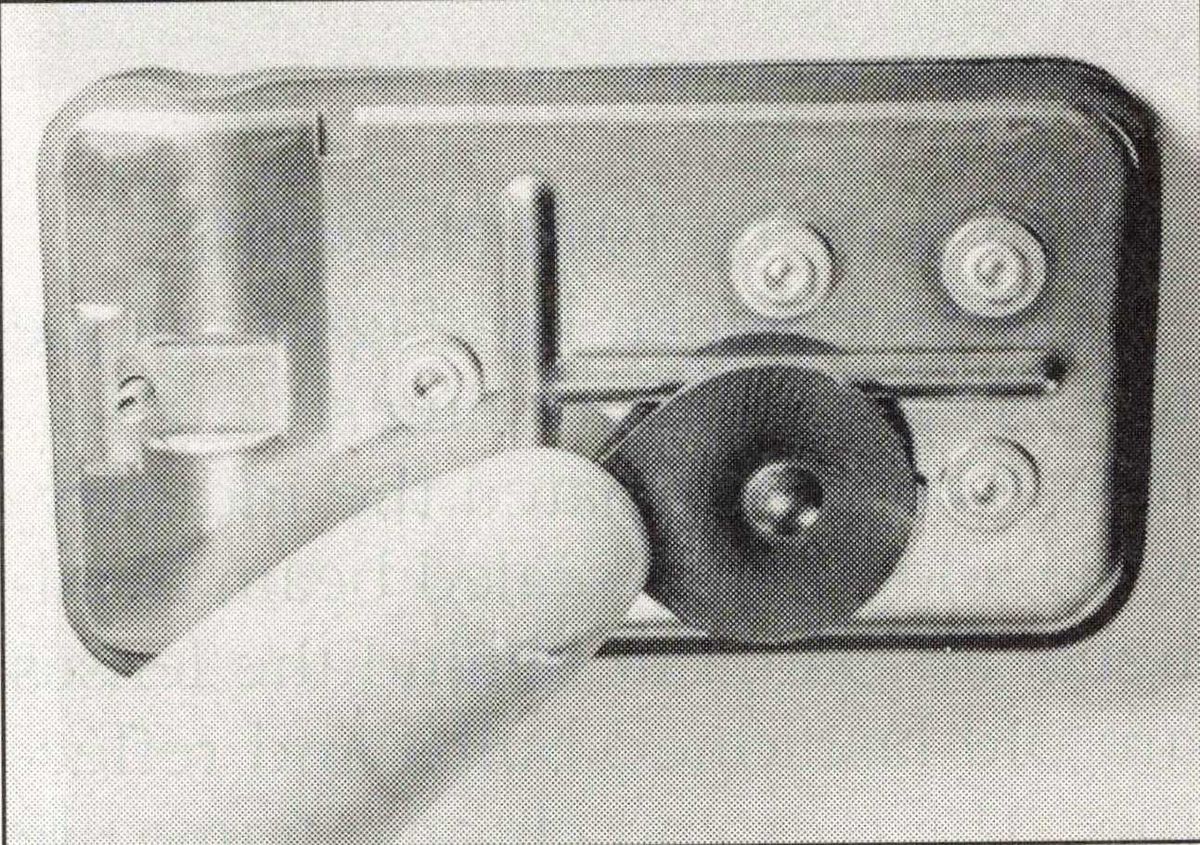

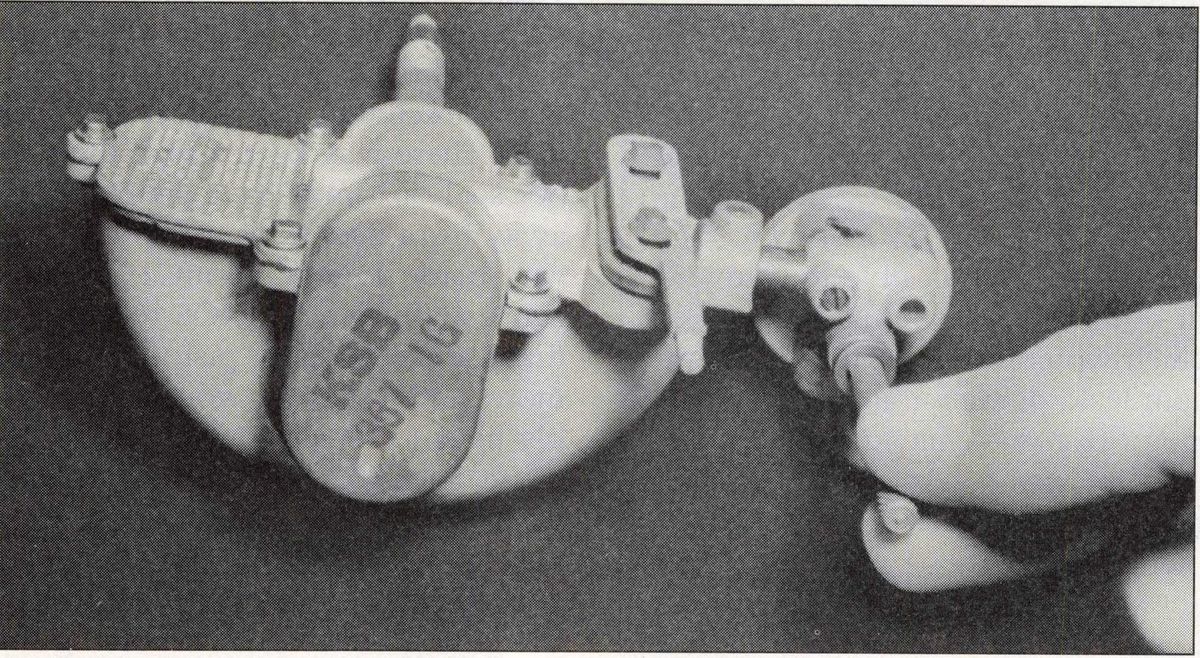

If the switch and cable are operating properly and the motor is getting adequate vacuum but the wipers still don’t work, the problem is in the transmission mechanism or the motor itself. The wiper motor contains a single piston upon which the drive lever is mounted. The motor’s piston does not resemble an engine piston. Instead, it is a flat, rectangular, two-piece assembly that swings back and forth within the motor’s case. Because it is flat, the piston is often referred to as a “paddle”. A valve located in the motor (called a “kicker valve”) directs the vacuum to alternate sides of the piston to move it back and forth in the motor housing.

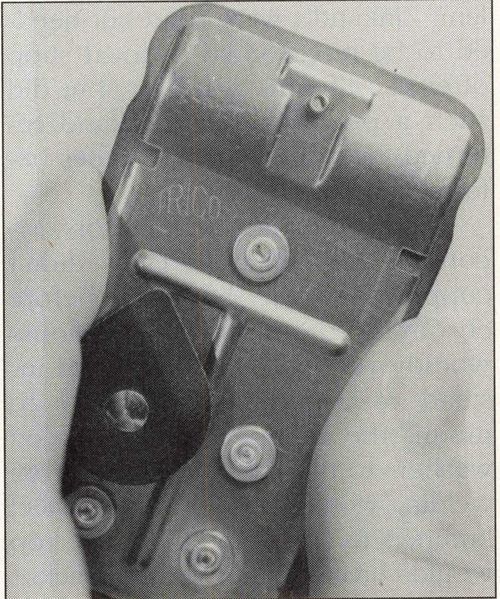

As the piston moves back and forth, the drive lever mounted to it also moves back and forth. The drive lever is attached to the wiper transmission so when it moves back and forth the transmission also moves back and forth and the transmission transmits this motion to the wiper arms, thus creating the action of the wipers on the windshield. Disconnect the wiper transmission from the motor to isolate one from the other. If the transmission in your unit consists of steel arms, then it can be disconnected from the motor by removing the clip that retains the arms to the drive lever. This clip can usually be accessed only from behind the firewall, underneath the dash. If the transmission in your car consists of steel cables attached to pulleys, then it can be disconnected by removing the motor from the base where it’s mounted. The motor normally screws to the base and the drive lever of the motor is coupled to the drive shaft in the base. The base remains connected to the cables and pulleys while the motor is removed. With the motor disconnected from the transmission, try to operate the transmission by hand. If you cannot operate the wipers by hand because the transmission won’t move, there is some kind of mechanical obstruction in the transmission or in the wiper-arm pivots. If the transmission moves easily by hand but the wipers still don’t move, there is a break somewhere in the transmission linkage or the wiper arms are slipping on their pivots.

If you can operate the wipers by hand after the motor is disconnected, then the inability of the wipers to function is due to a problem in the wiper motor. A common problem in vacuum wiper motors is a stuck piston. The factory packed lithium based grease in the motor when it was assembled and after 40 or 50 years the hardened grease can immobilize the piston. The likelihood of this problem developing is increased because most collector cars aren’t driven in the rain and the wipers are rarely, if ever, used. If you experience this problem, the solution may be as easy as cleaning the old crusty grease and dirt and lubricating the motor with new grease.

Another common problem with wiper motors is an inadequate seal around the perimeter of the piston. The piston has a pair of thin rubber strips around its edge to seal it against the motor housing so the vacuum directed at the piston does not leak. There may be a tear in the rubber seal or it may have simply worn away from use. If your wiper motor was made before about 1948, you can usually buy an NOS rebuild kit that includes a new piston. If it’s of more recent vintage, you will probably have to repair your old parts because Trico (the manufacturer of vacuum motors) did not market rebuild kits for the later motors. Repairing your original piston is accomplished by drilling out the rivets holding the metal strips that retain the seal, installing a new seal and re-riveting the retaining strips. If a seal is not available, it usually can be improvised from a seal that is available.

A less common problem with motors is warpage in the body that prevents the piston from sealing through its full range of motion. Minor warpage can sometimes be repaired by a skilled person using a press or vise to alter the shape of the motor. This is risky for the inexperienced person, however, because the housings are made of pot metal and can easily crack. If a warped body is preventing the motor from functioning, the best solution usually is to replace the motor with a good used unit.

Although much less common than a stuck or leaking piston, another problem with wiper motors is a vacuum leak. Though unlikely, it is possible for leaks to develop where the top lid of the motor is mounted to the housing or in the housing itself. To test the motor, connect a handheld vacuum pump to the motor’s vacuum port and apply about 10 or 12 inches (Hg) of vacuum. Leave the pump connected to the motor for a minute or so and observe the pump’s gauge. If the vacuum drops, it indicates a leak somewhere in the motor. If a visual inspection does not reveal the leak, you should introduce about 20 psi of compressed air into the motor through its vacuum port and submerge the motor in water. Air bubbles rising in the water will reveal any vacuum leaks.

Sluggish Wipers

When vacuum-powered wipers function but their action is sluggish, it is usually a result of one or more of the same problems that cause wipers to fail altogether. Check the supply of vacuum just as you would if the wipers were not working. Also, make sure the system’s moving parts, including the motor’s piston, the trans mission, and the wiper-arm pivots, are not binding or gummed from old lubricant and dirt. Try to operate each moving part by hand and if you feel excess resistance, repair the source of the bind or clean and lubricate any dirty parts.

Transmissions that use steel arms (as opposed to pulleys and cables) usually have small, oil-impregnated felt washers between the arms where they are riveted together. Clean the felt with some mild solvent (like Permatex Brake Clean), blow dry with compressed air, and oil the felts with light-weight oil. If the washers are missing, you can cut new ones from a sheet of felt (available at a hobby or fabric store) and slip them into position. To assure proper thickness, use the old felt washer as a thickness guide or take a measurement with a machinist’s ruler.

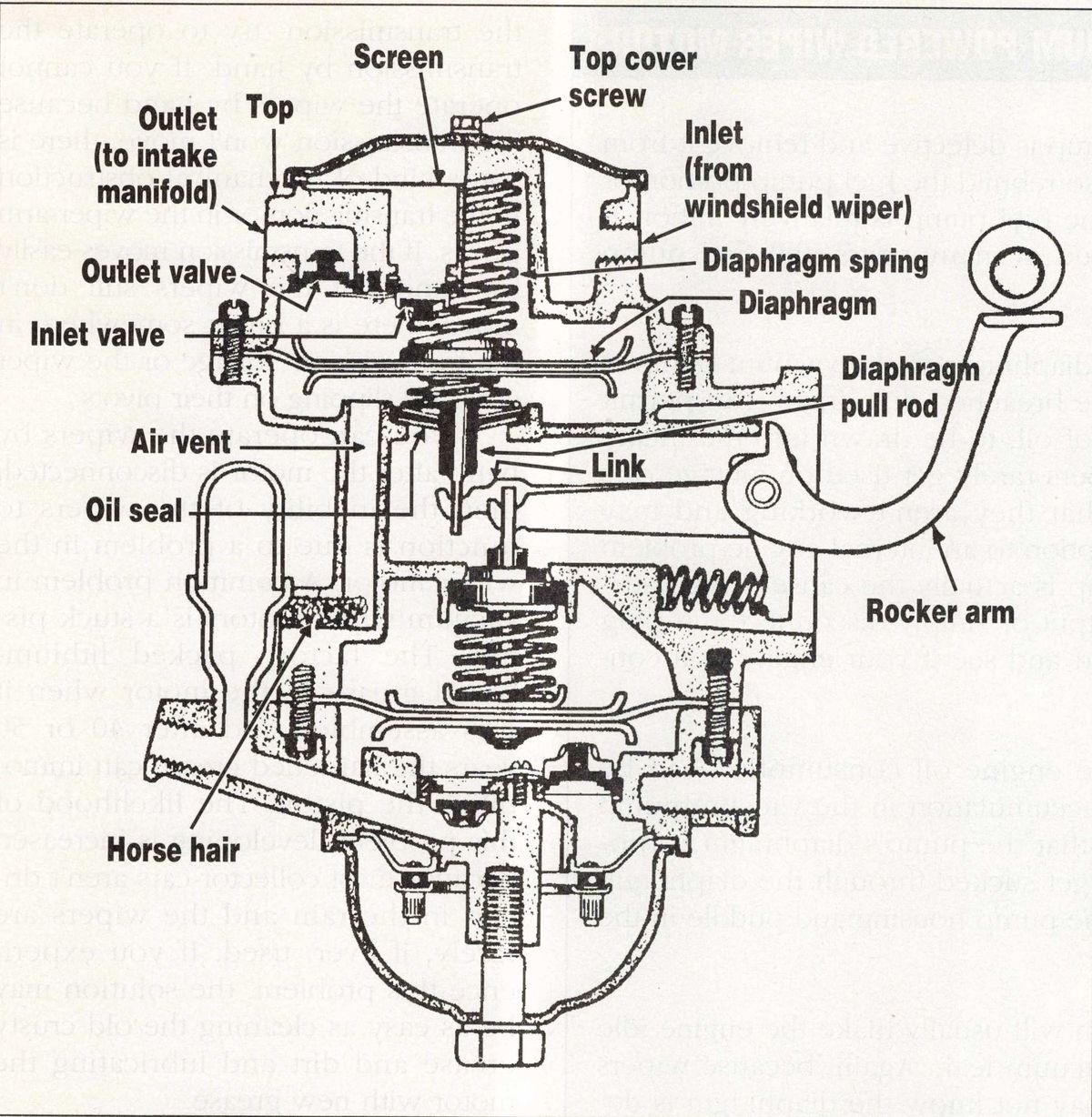

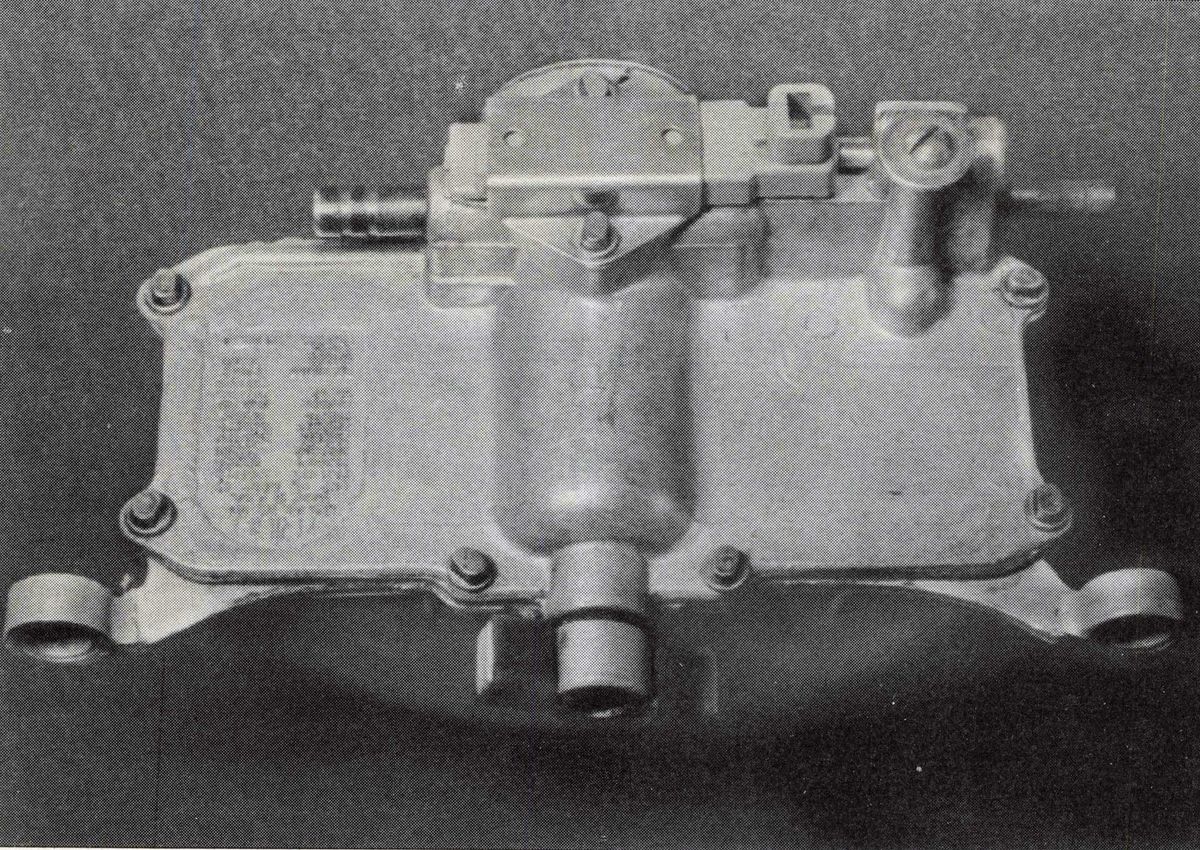

If your wipers function adequately when the car’s engine is idling or when the car is driving at slow, steady speeds, but slow down a lot when the car is accelerating or traveling at highway speeds, there is a malfunction in the vacuum pump. The vacuum pump may be leaking where the top meets the main body or the main body may have a crack, but a more likely source of the trouble is a ruptured diaphragm or defective valve inside the pump.

Begin your diagnosis of the pump by disconnecting the hose leading to the intake manifold and the hose lead ing to the wiper motor. Connect a vacuum gauge to the port on the pump that feeds vacuum to the wiper motor and plug the vacuum line that connects to the intake manifold to prevent a vacuum leak while the engine is running. Also, make sure the port on the pump that receives vacuum from the intake manifold is left open or the pump can be damaged. Run the engine at about 1000 rpm and observe the vacuum reading. At this engine speed the pump should produce a steady seven to 12 inches (Hg) of vacuum. If it doesn’t, the pump is defective and should be repaired.

Remove the pump from the car and disassemble it. Draw diagrams as you go if it helps you to remember which parts go where and in what order. Ninety-nine percent of the time the problem in a malfunctioning pump is a ruptured diaphragm or a defective valve, but it is also possible that part of the actuating assembly or the housing itself is the source of the problem. As you disassemble the pump, carefully examine each part for a damaged diaphragm or valve or possibly worn or damaged linkage.

To rebuild the vacuum pump you will need a rebuild kit for your particular car. You can purchase a kit from one of the sources listed in the resource box above or from your regular parts supplier. The kit should contain a new diaphragm, inlet and exhaust valves, diaphragm spring and assorted gaskets.

When reassembling the pump, be careful not to over-tighten the cover screws. Over-tightening can cause the covers or the pump’s body to warp, which can lead to leaks.

Some helpful hints concerning Vacuum powered wipers

1. If you determine that the vacuum pump is defective and remove it from the car for repair, it is a good idea to also rebuild the fuel pump portion of the unit. The cost of a rebuild kit for the fuel pump is relatively minor. If the vacuum pump hasn’t been serviced in many years, the fuel pump probably hasn’t been serviced either. ,

2. A possible side effect of a ruptured diaphragm in the vacuum pump is excessive engine oil consumption. The breached diaphragm can permit crankcase fumes; which contain a lot of oil, to be drawn into the intake manifold and burned. Because the wipers rarely get used on vintage cars these days, you may not be aware that they aren’t working and may wrongly attribute your car’s oil consumption to an internal engine problem when the malfunctioning vacuum pump is actually the cause. If you suspect this, test your vacuum pump’s output or simply disconnect and plug the line to the intake or carburetor port and see if your engine’s oil consumption decreases.

3, For the same reason that excessive engine oil consumption can be — caused by a defective diaphragm, oil accumulation in the vacuum pump casting recesses is often an indication that the pump’s diaphragm is ruptured. The oil-laden crankcase vapors get sucked through the diaphragm and over time the oil can seep out of the pump housing and puddle in the recesses.

4. A ruptured vacuum pump diaphragm will usually make the engine idle roughly or miss because it causes a vacuum leak. Again, because wipers are rarely used on vintage cars, you may not know the diaphragm is defective and will erroneously attribute the poor running engine to some other cause. Disconnect and plug the line to the intake or carburetor port and see if the engine runs better.

5. Whenever you test your wipers, make certain the windshield is clean and wet because wiping a dirty or dry windshield will usually scratch it. Also, before testing the wipers, carefully examine the blades to make sure — the rubber isn’t so deteriorated or torn that the metal portion of the blade will contact the windshield.

6. Trouble in the vacuum-powered wiper system, like trouble in many areas or older vehicles, is often the result of more than one malfunction or problem. Several minor deficiencies, which would do no noticeable harm by themselves — such as a slight vacuum leak, gummy transmission, and a moderately worn seal on the wiper motor piston — may combine to seriously impair wiper performance. Be aware of the cumulative effect of — several minor shortcomings and don’t assume that because you found one problem you have found the only problem.