Fundamentals of Engine Vacuum

For Something That’s Really Nothing, It’s Very Effective. Here’s a Look at How Vacuum’s Measured and Used.

VACUUM IS UNIVERSALLY used in automotive engines to provide the force required to actuate servos, such as the brake assist and spark advance. Interestingly, vacuum does not provide any force itself…yet specialists and weekend hobbyists alike constantly refer to something called “vacuum assist.”

So, before we discuss some of the various mechanisms that use vacuum and how they’re able to use it, let’s first clarify just what we’re talking about here. The dictionary defines vacuum as “a space entirely devoid of matter,” and this “matter” also means “air.”

Working With Mercury

How is vacuum measured? One would think that we can measure vacuum as a negative pressure, that is, in “pounds per square inch.” Not so. Vacuum is measured in inches of mercury.

Figure 1 shows the dial of a high-quality vacuum gauge. No vacuum is “zero,” and maximum vacuum is “30.” The units are “inches of mercury.” On the dial it is written “in. Hg” with Hg, of course, being the chemical symbol for mercury.

Where does this measuring system come from? The earth is surrounded by a layer of air (also known as “the atmosphere”) and while it might sound curious, air is heavy. The weight of the atmosphere exerts a pressure on the earth and this pressure, at sea level, is 14.7 pounds per square inch.

As it is cumbersome to use this “14.7” number, scientists call it “one atmosphere,” or a “BAR.” This pressure is the same as one generated by a column of mercury 29.92 inches high. Therefore, we say that one atmosphere is equivalent to approximately 30 inches of mercury.

Inside a Barometer

The instrument used to measure both the atmospheric pressure and vacuum is a “barometer” and Figure 2 shows the workings of one. It is a glass tube bent in the shape of the letter “U,” and it is more than 30 inches tall. The tube is filled with mercury so that the level in each side of the tube is 15 inches. If all this seems like a classroom lecture, please bear with me a little bit longer—to understand vacuum we must understand how it is measured.

Now let’s suck all the air from the right side of the barometer tube. The atmosphere applies a pressure on the mercury from the left side (and only on the left side) of the tube, and forces it downward. How far does it push? Until the column of mercury in the right side becomes 30 inches higher (to be exact: 29.92 inches). Therefore, we can say that the maximum vacuum that can exist at sea level is 30 inches.

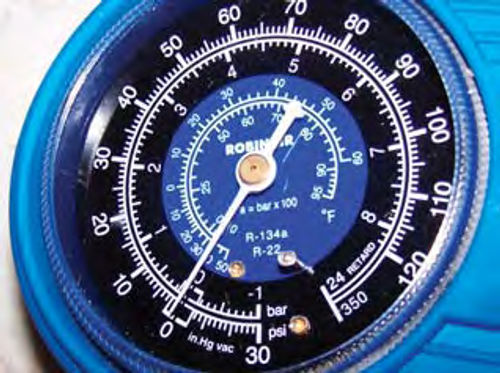

One instrument used in connection with air conditioning is a combination pressure/vacuum gauge (Figure 3). A magnified lower corner is shown in Figure 4.

The outer scale shows pressure in “psi” (pounds per square inch), and to the right of zero it shows vacuum in “in. Hg” (inches of mercury).

The inside scale shows the same things, but the units are “bar” (which is an abbreviation of barometric pressure).

An interesting thing to notice is that one bar is the same as 14.7 psi, and minus one bar is the same as 30 in. Hg.

Generating Engine Vacuum

OK, that’s enough theory. Let’s see how vacuum is generated in a vehicle’s engine. The pistons move from the top point to the bottom point in their respective cylinders, and in the process they suck air in through the carburetor (in older vehicles).

If the engine is at idle, the butterfly valve is closed and does not allow much air to be sucked into the engine. Therefore, a vacuum is created inside the intake manifold.

Because nothing is perfect, the maximum vacuum that can exist in an intake manifold is about 20 inches. This vacuum, in turn, is transmitted through rubber tubes to the vehicle’s various “vacuum assist mechanisms.”

The Pressure Does the Work

Figure 5 shows a simplified mechanism; just a cylinder with a piston inside, and a weight is hung from the piston. Once vacuum is applied to the top of the piston, the weight is lifted.

But the force to lift the weight is not provided by the vacuum, it is provided by the atmosphere!

It is easy to calculate the amount of weight that can be lifted. Let’s say that the piston radius is 2 inches; the surface area of the piston is (3.14 x radius squared) = 12.56 square inches. If the vacuum is 20 inches, the atmosphere pushes the piston upwards with a force of 123 pounds! That’s a lot of force available to actuate a mechanism, such as the brake-assist.

And what did we learn from these calculations? Obviously, it’s not the vacuum that provides the force…it’s the atmospheric pressure.

Given this force at work, the vacuum gauge becomes an excellent diagnostic tool. If we read a constant 20 in. at idle, everything is OK. As we accelerate the engine the amount of vacuum drops, but it still should be constant. If the vacuum gauge oscillates continuously, it could mean a number of things, such as a sticky valve, worn valve guides or even weak valve springs.

To get a meaningful reading, all the items attached to the manifold must first be disconnected.

For instance, if the engine is supercharged, and quite a few are (even antiques), instead of reading a vacuum, we might read a pressure. If the engine is equipped with a vacuum pump, we will read the performance of that pump, rather than the engine vacuum.

A Look at These Attachments

A supercharger, of course, is used to boost the engine power. Even with the carburetor butterfly fully open there is some restriction to the air inflow; mainly from the narrow carburetor passages, and from the restriction imposed by the air filter. Since it’s air flow that carries the fuel into the engine, to increase the fuel flow some cars are equipped with a blower that forces air into the carburetor. Although desirable for engine performance, the blower does not allow for an accurate vacuum reading.

Old vehicles equipped with vacuum motors for windshield wipers suffer from frustrating wiper performance. Let’s say you are driving through rain, going downhill. With your foot off the accelerator, the engine vacuum is large, and the wipers work at high speed. Now comes a hill, so you accelerate to provide the needed power. As the butterfly opens the vacuum decreases, and the wipers slow down…and sometimes they’ll even stop completely.

Car manufacturers used two methods to prevent this driver frustration: they incorporated a vacuum reservoir, and some of the cars even have a vacuum pump, integral with the fuel pump. For these items to work, a check valve is needed. The Figure 6 schematic shows the placement of this check valve.

Some drivers believe that the vacuum reservoir is also needed for the brake assist device. Not quite, as brakes are applied only when the right foot is off the accelerator, hence the engine provides maximum vacuum. However, the vacuum reservoir provides the required vacuum in case the engine stops, allowing us to safely stop the car.

Let’s look at the schematic, and follow the air flow.

When engine vacuum is high, the air is sucked, passing by the ball of the check valve, from the reservoir into the intake manifold. Even though the vacuum pump works also, inefficiently, it has no influence on the amount of vacuum at this time.

When the engine is accelerated, and the vacuum in the manifold is low, air could be sucked into the engine from the reservoir, but the check valve closes, therefore the vacuum from the reservoir is still available for the windshield wiper motor, at least for a while. The larger the reservoir, the longer the wiper motor works, even at high engine RPM. At the same time, the vacuum pump also works at high speed, and helps maintain the vacuum in the reservoir. The pump does not suck air from the intake manifold, as the check valve is closed.

In my 1947 Lincoln with a V-12 engine, I replaced the rather small factory reservoir with an old refrigerant bottle. Now the wiper motor can operate, even with the engine shut down—for about 10 minutes!

Replacement Check Valves

As stated before, when the engine vacuum is used for diagnostics, the connection from the manifold to the check valve must be plugged.

Also, OEM check valves often go bad, and without them the system does not work. Fortunately, modern cars still use vacuum check valves, and replacements (Figure 7) are readily available. When installing a new valve, first determine which port must be connected to the manifold. This determination can be easily done: suck from each port...the one from which you can suck air should be connected to the manifold.