WHEN YOU’RE PULLING OR INSTALLING AN ENGINE…

Let’s Look At Some Types of Hoists That Will Help You to Lift Heavy Loads Safely and Efficiently.

Editor’s note: We’ve recently had readers’ questions and insight regarding the pulling and installing of engines, so veteran restorer John Gunnell offered to take an in-depth look at the subject and he sent in this report. And remember readers, anything you want to add to this ongoing discussion is always welcome.

Taking an engine out of a car or truck typically requires 5-8 hours of work. It’s not just a matter of lifting the heavy engine; the job also involves disconnecting mechanical linkages, plumbing and electrical wiring. Sheet metal panels may have to be removed to clear a space for the engine to be raised through. The steering column and wheel may need to be detached and interior parts may need to be moved out of the way, too.

At $75 per hour a commercial shop might charge $375-$600 for this job and then charge an equal amount to put the same type of engine back into the car. If the replacement engine is of a different type that requires new engine mountings to be fabricated and other modifications to be worked out, then the job will cost even more.

However, the good news is that most restoration hobbyists can do this work on a do-it-yourself basis if they have a little experience turning wrenches and some type of engine hoist.

First You Remove the Hood…

The hobbyist will start by removing the car’s hood and any sheet metal that’s in the way of the engine coming out. Then they’ll disconnect the wires, cables, fluid lines and linkages that go from the car to the engine. A good shop manual will list all steps involved in taking a certain engine out of a specific car. To put it (or another similar engine) back in the car, you’ll reverse the steps.

As you work, take lots of digital photos and keep a book handy to jot down notes. It’s great to have an old computer in your shop that you can type every step into. Have zip-up food storage bags, index cards and a pen nearby. Each time you remove a part toss it in a plastic bag, write it on the index card and put the card in the bag. Keep grease and oil out of the bag and don’t store it in the sun or the writing on the cards will fade.

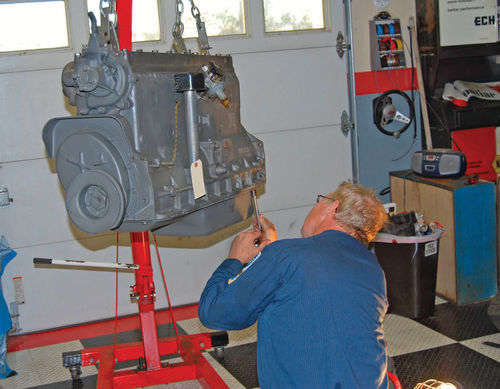

As you move along, more and more parts will come off and the remaining parts will get easier to visualize. Eventually, you’ll see how the engine mountings work and figure out how to remove them. At this point, you can move in with your hoist and lift the engine out of the chassis. Some engines have lifting attachments for hoisting, but often you’ll have to put a sling around the block to lift it. Chains can be used, but they can cut into new engine paint, so think about a rope sling or a cradletype sling made out of tow straps.

One Method To Avoid

The simplest way to lift a car or truck engine is to use a chain hoist with one end safely hooked to a very strong tree limb or a very strong garage beam. The other end will have hook that can be attached to a chain or strap securely wrapped around the engine. We’re not recommending this style of lifting because it can be dangerous. One hobbyist we know was injured while lifting an engine over a tree limb. Not only did he take a trip to the hospital, but his engine wound up swinging from the tree for several weeks!

Here’s a Better Way…

An engine hoist is a better and safer piece of equipment to use for lifting an engine. Back in our hobbyist days, the first engine hoist we had was an ugly yellow, beam-type lifter that resembled a pallet jack with a lifting arm and hydraulic ram. It had metal “skate type” rollers. We saw this advertised for under $100 in a local shopper-type newspaper and bought it. The funny thing is, it worked pretty well and many years later, after one of the skate wheels wore out, we were still able to resell the hoist for $75.

Lifting an engine straight up was no problem for the yellow hoist due to a couple of factors. First, the legs were far apart, which made the lift hard to tip over, even if you were trying. The hoist beam and arm were attached to a heavy plate that ran from one leg to the other and kept the load stable. The hoist was heavy, which also made it difficult to tip over. It was also a bit cumbersome and hard to store due to its size.

Our Current Approach

Today we have a “cherry picker” style engine hoist with legs that fold up so that it can be stored more easily. With this kind of crane, don’t try lifting an engine unless the legs are extended all the way out at the bottom. If you don’t extend the legs and lift up a heavy engine, you might not be able to support its weight and the hoist may tip over.

An Online Aide

The Website www.knockoutengine.com contains helpful information about many of the popular engine hoists available in the market today. It provides details on manufacturer pricing, lifting capacity, jack capacity, “foldability” and the number of boom positions for each of the hoists. It also rates most models on a 1-star to 5-star scale. Prices range from under $200 (2 1 ⁄3 stars) to $6408. The latter has no star rating because no customers reported buying and using such an expensive model. Several of the highest-rated hoists are 4-star models that are available for under $350. If you are thinking of buying a cherry picker hoist for your shop, you’ll want to check this Website.

Home-Made and StoreBought Gantry Cranes

Instead of a garage beam or tree limb that might break, a gantry crane can be used in conjunction with a chain hoist to lift an engine. In the June issue of Auto Restorer reader Steve Davenport of Nashua, New Hampshire, wrote in about the wooden engine hoist he made years ago. Mr. Davenport sent a photo of it being used to pull a pickup truck engine. It was of gantry crane style. Hot rodder Trent Lewis, of Eau Claire, Wisconsin, also made a very nice hoist from metal pipes. Mr. Lewis’ hoist had dolly wheels on which it could be moved.

A gantry crane we bought from Harbor Freight also does a great job of lifting heavy car assemblies. We’re sure that this unit cost more than a hoist made out of wood or pipe, but we were in a commercial building and had to keep the property insurance agent happy with a store-bought crane. Another advantage was that the crane’s height was adjustable.

We also envisioned using our storebought gantry crane to lift and install a 1948 Chrysler body on the car’s restored frame. To do this, we required a crane that could handle the weight of the large car body. The store-bought crane was certified and approved for a load within the weight range we were handling.

This heavy-duty piece of equipment is called a Pittsburgh Automotive 1-ton capacity telescoping gantry crane. It carries a list price of $750, which was more than we really wanted to spend. Harbor Freight ads often include 20 percent off coupons. So, we clipped a few coupons and waited for months until the gantry crane went on sale.

The bottom line is that we bought the gantry crane for $593, realizing a savings of $157. We also used two additional 20 percent off coupons to get $12 off each of two trollies that are designed to ride on the top of the crane. We paid $95.98 for these, instead of $119.90, a savings of $24. We also had to add two 1-ton chain hoists at $49.99 each, or $99.98. That made the total price of all this equipment a pretty reasonable $808.88.

Some Helpful Accessories

Our old yellow beam-type hoist could lift an engine almost straight up as long as you used a device that allowed us to balance the engine’s weight as it was lifted. Some manufacturers call these Engine Hoist Levelers and some call them Engine-Lifting Equalizers. Most of them have a 1500-lb. working load capacity that accommodates most engines. A worm drive shaft rotates for easy balancing action. We got our load equalizer from Eastwood.

British car parts supplier Moss Motors also sells the Tilt Lift, a $100 device that allows easy adjustment of an engine’s lift angle through a full 90 degrees of movement. Adjustment is easy with a ½-inch ratchet wrench. The 2000-lb. capacity—with a 3:1 safety load factor— is enough for any modern engine/ transmission combination. A positive lock ensures that the engine stays put. The Tilt Lift is small in size and weighs only four pounds. It’s ideal for small work areas. The mounting cleats are adaptable to any engine.

These are just a couple of devices that come in handy for lifting an engine or other heavy auto parts. Whatever equipment you use for jobs like these, be sure they can safely carry the load you’ll be subjecting them to. Engine removal or installation is a big job. Go slowly and safely and make sure you have the right tools for the job at hand.