Finding parts for auto restoration

A friend of mine constantly jokes that the hardest part of restoring a collector car is finding parts made of “unobtanium.” Of course, you’re not going to find a listing for unobtanium in the Periodic Table of Elements because it’s simply a word coined to imply that certain parts are very rare. You might expect a vintage piece of chrome or a mechanical part for an old car to be rare, especially if the car is a low-production model like the one we happen to be working on in my shop. On the other hand, you’d probably laugh if we said we were having problems getting nuts, bolts and washers for that car. Heck, these items come in SAE, Metric and—in rare cases—Whitworth sizes, don’t they? Just go to the local hardware emporium or Fastenal store and buy what you need. If that doesn’t work, break out your McMaster-Carr Catalog (mcmaster.com).

The car in question is a 1948 Mopar product and we even have an original illustrated parts catalog for it which lists some of the fasteners and the specifications for them. For instance, on page 268 of the parts catalog there’s an illustration of the rear leaf spring parts, which Chrysler cataloged as Group 17 components. The bolt that goes through the front eye of the spring is labeled Bolt 17-17-4.

When you flip to page 275 where the Group 17-17-4 parts are listed, this bolt is described as: “Bolt, Rear Spring Silent Bloc. Hex-hd., S., 5/8-18 x 3-1/4.” It is Mopar part No. 668 265 and two were required. The nut for this bolt is described as: “Attaching, Standard Part. Nut, lock, hex, thin, S-fin., S., pln., 5/8 in.-18.” There is no washer because the nut is an old lock nut. These circa-1948 lock nuts are not the same as today’s Nylock nuts. The originals somewhat resemble a castle nut, but are more like a standard nut with slits cut into it. As you tighten the nut, the slits are pressed together and “lock” the nut in place.

The abbreviations in the description of the bolt are easy to decipher. It is a hex head (hex-hd.), steel (S.) bolt that is 5/8 inch in diameter with 18 threads per inch and 3-1/4 in. long (5/8-18 x 3-1/4). The description of the nut indicates it is a locking nut (lock), with a thin hex shape (hex, thin), semi finish (S-fin.), made of steel (S.), plain (pln.) which is 5/8 inch in diameter with an 18 threads per inch internal thread (5/8 in.-18). The description does not tell you this, but the bolt is threaded from the tip for only about one-quarter of its length and the hex head is fairly thin for a large bolt.

We Searched and Found the (Wrong) Bolts

This car’s owner wants his vehicle to be restored as close to original as possible. When the job is completed, he doesn’t want to take it to a show and have a judge tell him that they didn’t have Nylock nuts in 1948 or that the head of the Rear Spring Silent Bloc bolt is supposed to be six- sided instead of square. He doesn’t want the fasteners to look brassy colored when they are supposed to be steel. In other words, he wants things to look the way they did at the assembly plant in 1948.

With such complete specifications for both the bolt and the nut, you’d think we could source a replacement from one of the sources listed above. Unfortunately, we couldn’t. So we paid a visit to Accurate Alignment (www.accuratealignment.com) in Appleton, Wisconsin, a shop that has helped us with other old car projects. In fact, they re-arched the leaf springs for this car. We did actually purchase bolts from them that would do the job, but they didn’t match the originals. They had a thicker hex head and were all-thread style bolts. We could probably have “lived” with these two differences, but they were also Grade 8 bolts with a copper-colored coating and they were 3 1/2-inches long. Later, we were shown bolts at a Fastenal store. Neither was what we needed.

Even Fasteners Lead to Important Choices

We were learning that it’s not easy—and in some cases impossible—to buy correct- looking fasteners for 60- or 70-year-old cars. The only way to get some factory- style hardware is to have it made, rather than buying it. But this takes time and money and can add a lot to the cost of a restoration, so vintage car owners should consider this when planning a restoration project. Furthermore, once the vehicle is put together, it becomes a major job to replace certain fasteners that don’t look “right.” In other words, it’s easier and cheaper to find/make correct fasteners in the first place.

Along with focusing on appearances, however, car owners may also want to consider how fasteners can affect the safety of a car. We’d venture that a modern Nylock nut is going to hold things together

more securely than those 1948 slit-type lock nuts. Similarly, a Grade 8 fastener, with its brassy coating, might be stronger than a steel bolt and even look nicer. However, it’s not going to look original. So, the car owner has to decide if safety, strength and durability factors are more important than an original look.

They Looked Right In the Picture...

In addition to the large bolt that attaches the leaf spring, the same 1948 Mopar model used a number of 7/16-20 size lock nuts on various front and rear suspension parts. These lock nuts were of the same slit-type design used on the larger spring bolt and were equally made of “unobtainium.” We could get nuts with a 7/16-20 thread at any store that sold hardware, but modern nuts of this size are lower and wider than the 1948 ones and are not lock nuts. If you want a 7/16-20 lock nut, the hardware stores carry Nylocks. Neither of these options was anywhere close to the factory original appearance that the car’s owner wants.

Next we tried eBay, clicking through dozens of listings for “castle nuts” because we thought the old lock nuts were old- fashioned castle nuts. We actually found one listing that showed a picture that seemed to be what we were looking for. We ordered those, but what came in the mail were the lower, wider modern lock nuts. (We’ll use them for something else someday, but not on this car.)

A Hot Rodder Lends a Hand...and An Opinion

A friend told us about an old hardware store in a nearby town that might have some new old stock nuts of the type we needed. “When you go there, ask if you can see the machine shop downstairs,” our friend said.

At this store, we purchased some nuts that looked more like the ones we needed. They also had the 7/16-20 internal threads we needed, but externally they were significantly larger than the original lock nuts. It again was a case of “no joy,” but we did get a peek at the fascinating machine shop downstairs that our friend had mentioned. (We’ll talk more about that later.)

Eventually we went to see a man named Rex Evchuk who operates Waupaca Machine & Repair in Waupaca, Wisconsin ( ). Rex is a very serious hot rodder whose business does heavy-duty machine work and metal fabrication for foundries and mining operations, etc.

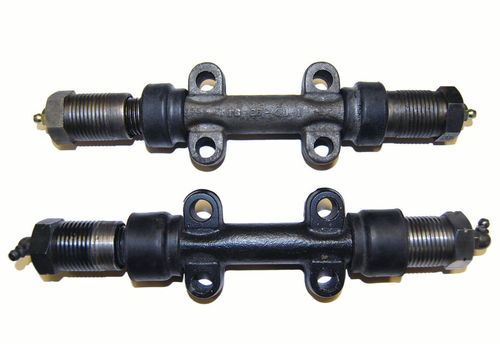

In our experience, there have been few machine parts that Evchuk can’t fix. We brought him the old lock nuts (we still thought they were castle nuts) along with one of the shock absorber mounting studs that we felt had excessive wear on it.

Evchuk informed us that the nut was actually an old-time lock nut and, as he usually does, he told us he couldn’t understand why car collectors need everything to look just like the day it left the factory. He always jokes that collectors should “upgrade” old cars the ways that hot rodders do.

Then he walked over to a wall of hardware bins and pulled out a regular 7/16-20 nut. “Let me see yours,” he said. “It looks about the same as this one, except for the slits, so we’ll just cut some slits in these for you. How many do you need?”

Evchuk then asked to take a look at the shock stud. We had the worn one and the one from the other side that had hardly any wear. “It will be easier to make you a new one like the good one, than to fix the wear on that bad one,” he said. “We can do that, but you’ll have to wait about a week until we get to it.”

We assured him that waiting wasn’t going to be a problem as the car is all-apart.

Other Parts Pose Problems as Well

The problem of new replacement parts not looking exactly like old parts isn’t limited to bolts, nuts and washers. Several suppliers sell parts for old Mopar cars (see the sources list at the end of this article), but the only parts you can usually trust to look exactly like the originals are NOS (new old stock) Mopar parts in the original boxes. Even NORS (new old replacement stock) parts made when these cars were still in use can have a different appearance than a factory part. This isn’t always true (we ordered NORS coil springs that looked totally factory), but more often than not, the non-factory parts have slight differences.

This was apparent when we ordered replacement shock absorbers. The shocks that came were priced right and well built. They fit perfectly, too. However, the original front shock absorbers were slightly fatter than the replacements and the new rear shocks did not have plates welded to them like on the shocks we took off the car. Of course, there is also the question of whether the shocks that were on the car were originals or replacements.

To make things even more confusing, the Mopar Illustrated Parts Manual indicates that two types of shocks were supplied on these cars from the factory. The earlier production cars used one- inch diameter Monroe shock absorbers in front and rear (the lengths differed from front to rear). Later production cars used 1 3/8-inch diameter Delco car with one-inch shocks had a shock replacement in the early ‘50s, it might have been re-fitted with the fatter shocks by a factory dealer.

Sometimes, You Just Have to Make Replacements

Reading the factory parts manual carefully can also be important in restoring a car to factory original condition. In the illustration of the rear leaf spring mentioned above, the use of thrust washers (Group No. 17-17-6) on either side of the Silent Bloc bushing is suggested by the drawing. However, the type of car we are working on came in three series. If you go to page 275 where the parts are listed and read the small print, you find that the thrust washers were only used on cars in certain series up to certain serial numbers. It turned out our car did not use them, even though they are shown in the illustration.

The same sort of thing was true in regard to the use of steel covers (also known as gaitors) on the rear leaf springs. We had noticed that there were no steel covers on the car we were restoring and we spent time on the Internet trying to learn if there was any source of the steel covers. Then, we read the fine print referring to certain serial numbers and discovered that the car we are working on did not come from the factory with steel spring covers.

As we move along with this restoration, we’re sure to run into other “unobtainum” parts that will call for modern duplicates. In some cases, NOS parts may show up and do the trick. There will also be some NORS or modern aftermarket parts that will fill the bill either “as is” or with minor modifications.

Finally, there will be certain parts that can’t be found anywhere and we’ll need to decide whether it’s practical and affordable to have replacements made or make replacements ourselves. It’s the nature of the business.

Doran’s Machine Shop

Now, back to that machine shop we mentioned a little earlier. While looking for what we thought were old castle nuts, someone suggested paying a visit to Wally Doran’s old hardware store. It was suggested that we “try to get a look at the basement.”

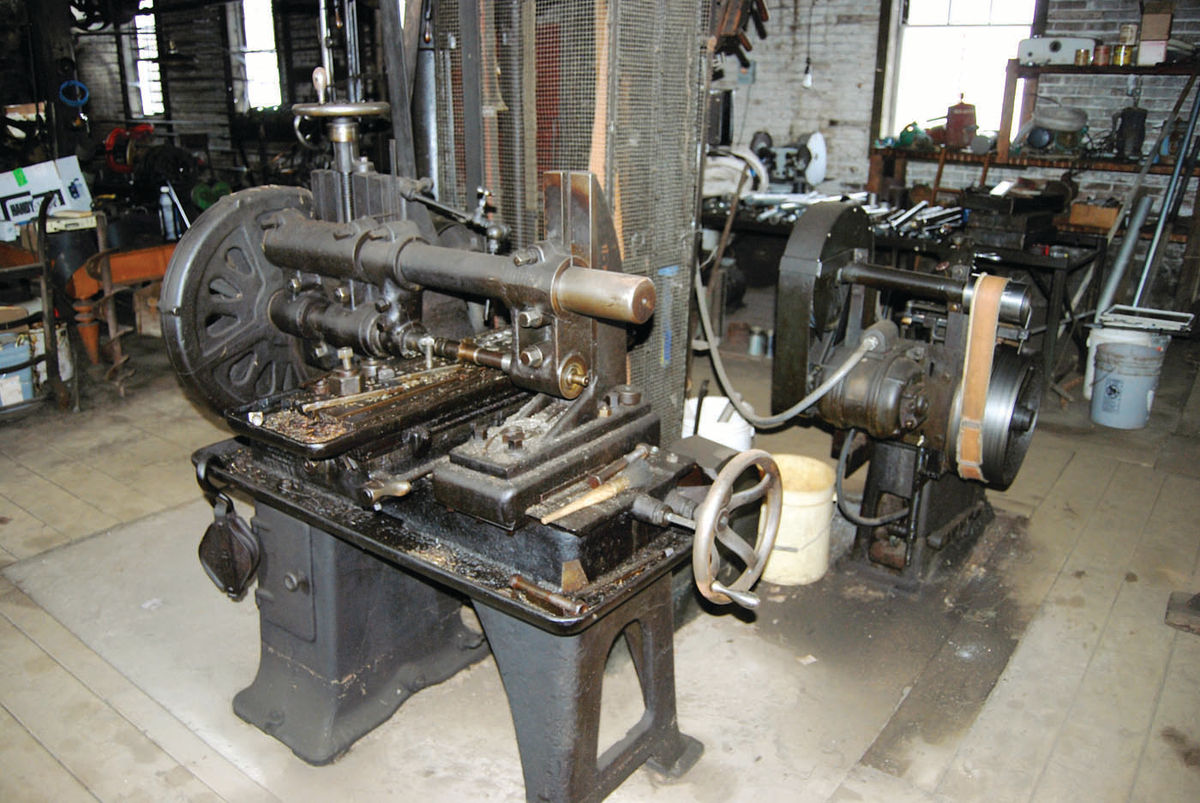

On our way there, we pictured a place with a horde of old nuts and bolts. What we didn’t expect was to see a machine shop with belt-driven machine tools that dated back to 1911 and earlier.

The store upstairs is old and fascinating, but entering the machine shop downstairs is like going back in time to America’s industrial revolution. A system of belt-driven overhead pulleys powers a variety of ancient machines. There’s a lathe, a pipe threader, a mill, a drill press and other mechanical marvels from a bygone era.

The W.J. Doran & Co. building dates back to 1907 when it was owned by a pioneer garageman named A.M. Hansen who transitioned from the blacksmith trade to automobile and farm machinery repairs. Hansen’s son took over the shop in 1942 and ran it until 1962, when he was hit by a car and killed. Doran bought the business in 1964 and has owned it since.

During my tour, he switched on the power and demonstrated how a few of the machines work. My guess is that they all work or could be made to operate again. But that really didn’t matter. The shop is like a living museum of United States industrial history. Only in small town America could you find such a treat as you’ll see in the photos on the next page.