1963 Studebaker Avanti

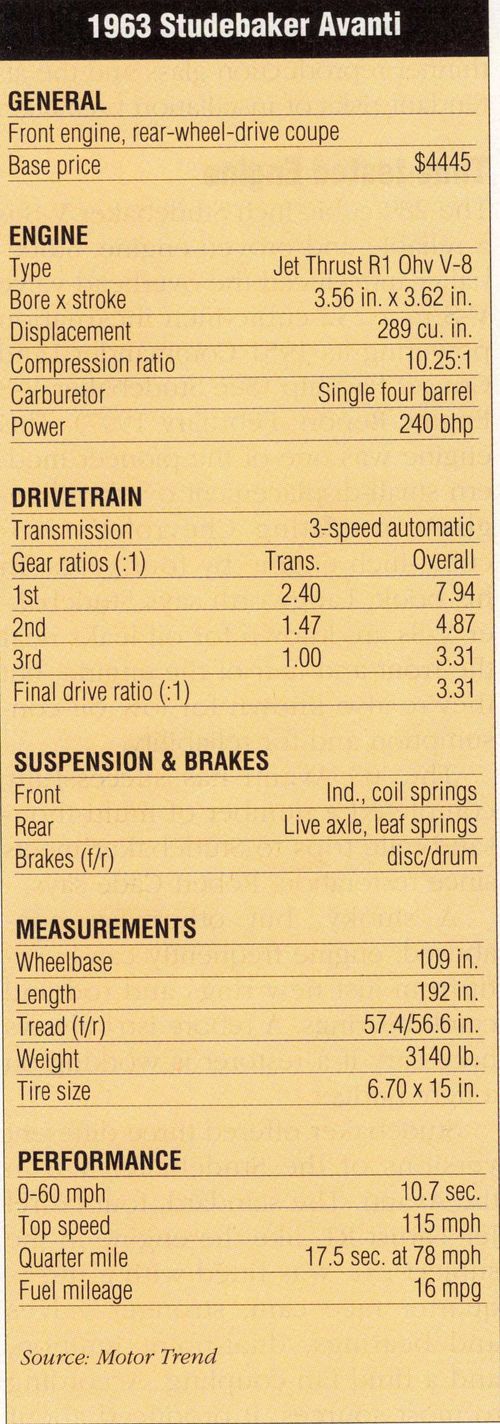

Market success doesn’t assure a car is good, just as market failure doesn’t assure a Car is bad. Take the Studebaker Avanti, for example. It has enjoyed far more success as a vintage enthusiast’s car than it ever did when new. Avanti was a market failure, fewer than 5000 were produced. The car probably did more harm than good for Studebaker’s sagging financial fortunes in 1963.

The Avanti seemed to inspire strong feelings, then and now. Newman & Altman, Inc., a large South Bend, Indiana, Studebaker dealership, liked the original Avanti so much the owners bought production rights when Studebaker folded. Under this ownership Avanti production continued, in one form or another, through 1990. But that’s another story.

Today, as a collectible car, a vintage driver or a restoration project, the original 1963-64 Studebaker Avanti is a technically unusual car, an engineering pioneer in many respects, and is a practical car to own and drive — as vintage cars go. The powertrains are reliable, parts are in good supply and decent cars are still affordable.

“You can get them in fairly decent shape for $8000 to $9000,” says Robert Cade, who owns four Avantis including our subject car. He will tell you they are excellent cars that were far ahead of their time.

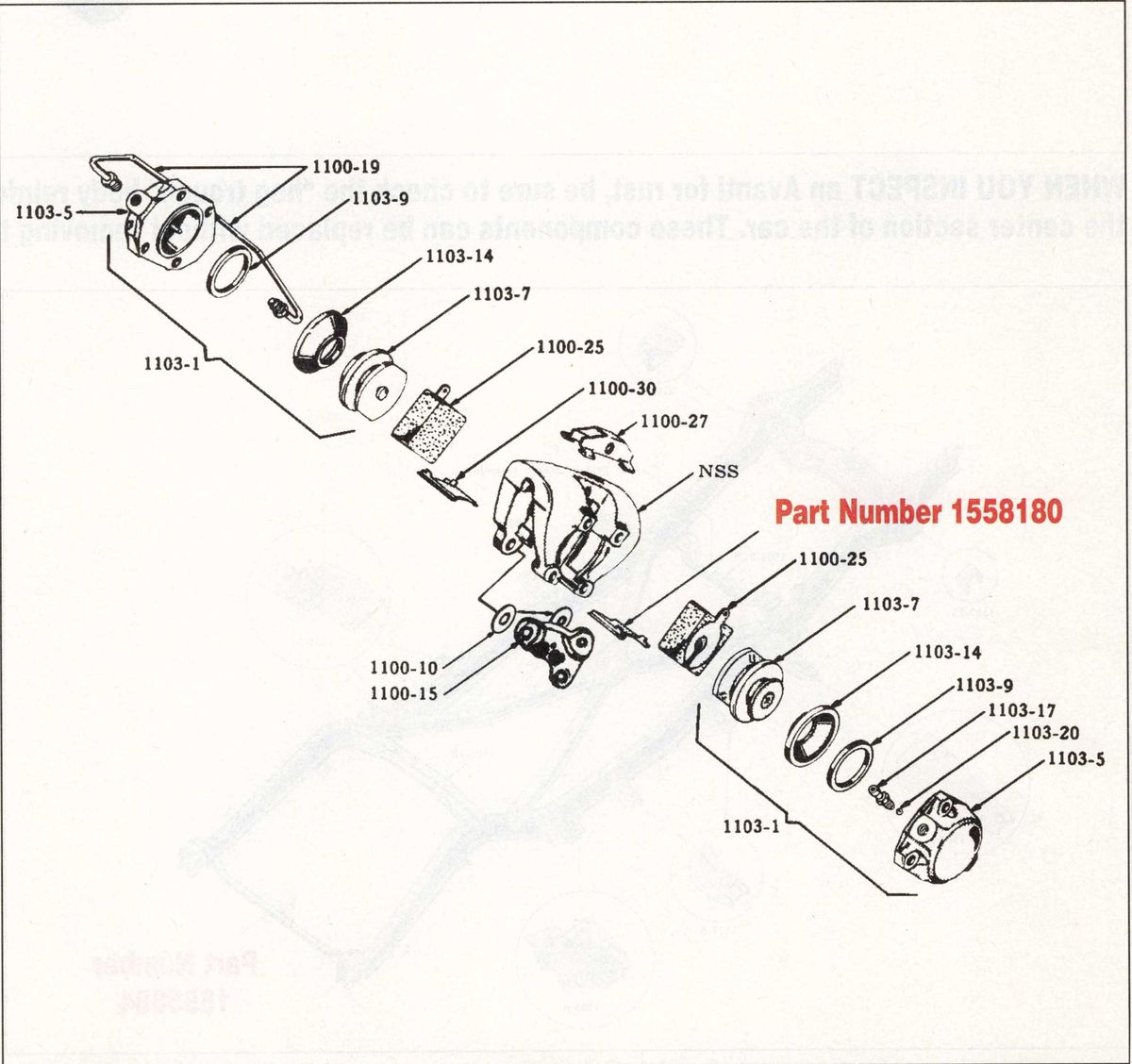

In his book “Studebaker 19461966,” automotive historian Richard M. Langworth noted the Studebaker system was the “first caliper discs in regular domestic production.”

In addition to the Bendix-built disc brakes, other safety innovations the Avanti offered were seat belts, a padded safety dash, safety door locks that helped keep the doors closed in a collision and a real roll-bar built into the B-pillar.

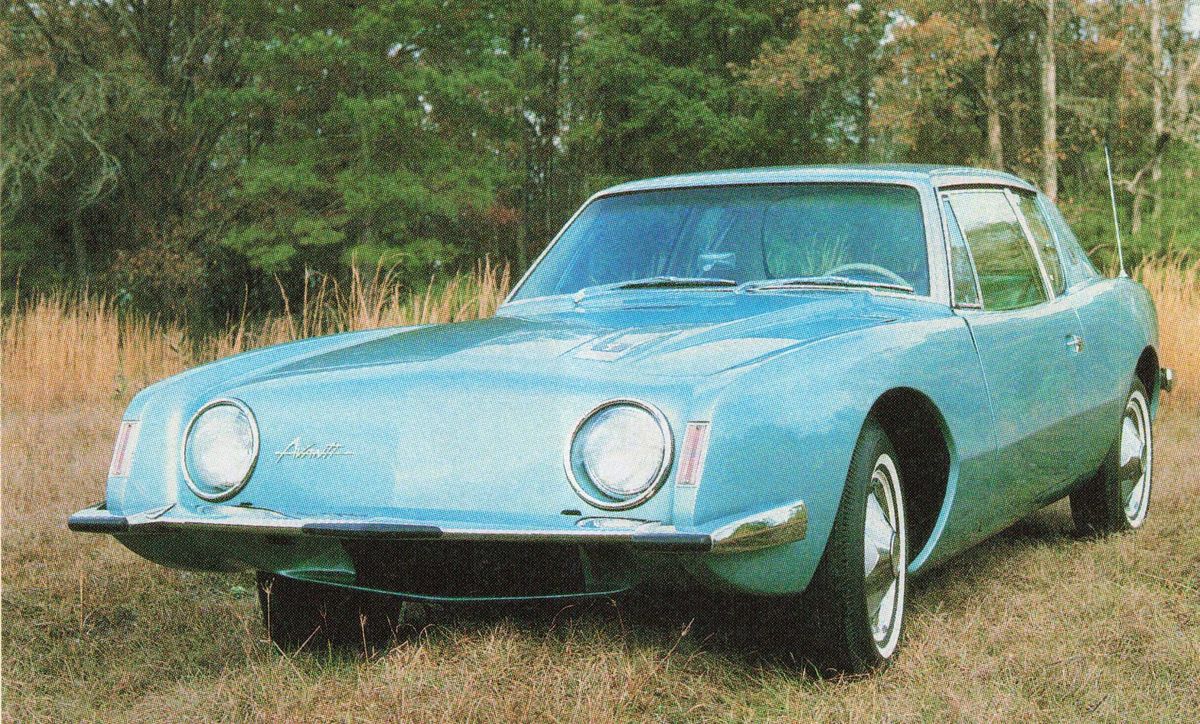

The Avanti’s body also was arguably ahead of its time, produced, like the Corvette, in no-rust glass-reinforced plastic (fiberglass) in a radical aero shape that still looks modern today.

And the 289-cubic-inch Avanti engines produced the benchmark one-horsepower-per-cubic-inch in Paxton-supercharged R2 form.

Cade bought this car in South Bend, Indiana, in 1984. It came with 102,000 miles on the clock, but he drove it home to Florida and used it as an “almost daily” driver until 1989, when he decided to do a complete, body-off restoration.

Avantis really are not problem cars to restore, he says, but plan on restoration costs running to $20,000 or more if you have to pay someone to do most of the work.

Since the restoration, the 1963 Avanti has covered about 34,000 miles. It usually does well at shows and has taken as high as second place at national Studebaker meets.

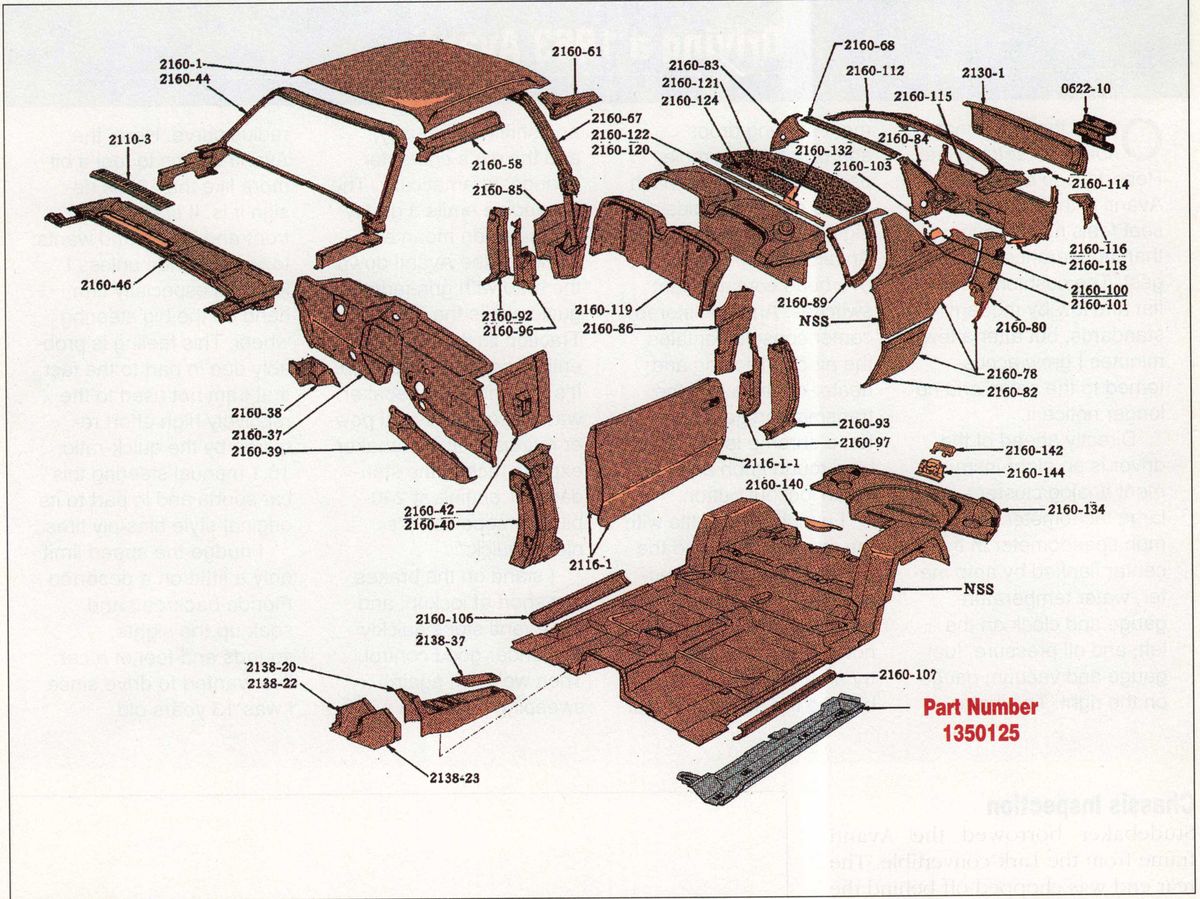

Body Restoration Tips

Body restoration requires a knowledge of fiberglass repair techniques. Five people can lift the body off an Avanti frame, Cade says, though the fiberglass body is not as light as one might think.

The Avanti bodies tend to get stress cracks near the back edge of the front fenders and on the rocker panels, though these are cosmetic and not structural problems, says Cade’s son, Stephen, who shepherds the family collection and has performed many Studebaker restorations. Such cracks are “not a safety problem — pretty much a superficial crack” and are easily repairable, he says.

Another problem common to Avantis is that the hinge boxes on the doors can crack loose from the fiberglass pillar. If the doors sag, this probably is the problem.

Properly weather-stripping the coupe’s long, heavy doors can be a tedious job, Stephen says. “It takes a lot of patience and time to keep them from leaking.”

Windshield replacement also can be troublesome, in part because reproduction windshield gaskets aren’t always a perfect fit and the windshields are big and heavy. The original windshield on the Cades’ Avanti has a few pits and imperfections, but they opted to stay with the imperfect original rather than replace it with thinner reproduction glass and the attendant risks of installation breakage.

Time-tested Engine

The 289-cubic-inch Studebaker V-8 is a reliable and proven engine. Studebaker introduced the overhead valve V-8 in a 232-cubic-inch incarnation powering its 1951 Commander Land Cruiser flagship (See Studebaker V-8 Engine Report, February 1997). This engine was one of the pioneer modern small-displacement overhead engines, predating Chevrolet’s 265cubic-inch engine by four years. In his book, Langworth says Studebaker V-8s are known for oil leaks near the front and rear of the engine, but they’re also known for low oil consumption and for reliability.

The ’63 Avanti has successfully completed a number of multi-thousand-mile trips to Studebaker meets since restoration, Robert Cade says.

A smoky, but otherwise non abused, engine frequently can benefit from just new rings and rod and crank bearings. A rebore isn’t always necessary if a restorer is working on a tight budget.

Studebaker offered three different versions of the Studebaker V-8 in the Avanti. The standard, four-barrel Jet Thrust R1, like the engine in the subject car, was fitted with a three quarter race cam, stronger valves and bearings, dual-point ignition, and a fluid fan-coupling. According to most sources, it produced about 240 horsepower.

The optional R2 engine received a sealed carburetor with Paxton supercharger in addition to the Rl modifications and produced about 290 horsepower.

The R3 engine, also an option, was similar to the R2 but was bored out to 3.65 inches from the ‘standard 3.56 inches for a 304.5-cubic-inch displacement and produced about 335 horsepower. Only nine of these engines were installed in Avantis, according to Langworth. Andy Granatelli drove an R3 to a record 170-plus mph at Bonneville in 1963. There also were super-exotic experimental R4 and R5 versions, but apparently none of these were bolted into production cars. Easy maintenance and parts availability are two reasons Stephen Cade appreciates the car. Superchargers can be rebuilt for about $400, and he recommends J.C. Herndon, in Marion, Texas, as one rebuilder who does a good job on the blowers.

Because the base Avanti engine is a hotter version of the standard Lark V-8, many internal parts such as pistons and cranks are interchangeable. Parts for a rebuild can run $500 to $1500, Stephen says.

To confirm original equipment and options on a specific car, Avanti shoppers can get build sheets from Newman & Altman. This information is especially helpful to those considering the purchase of a supercharged model.

Optional Transmissions

Studebaker offered three transmissions in the Avanti, a three-speed Flight-O-Matic, a four-speed manual and a three-speed manual (R1 only). Under normal conditions, the automatic starts in second but can be shifted manually for first-gear starts. The four-speed is a Warner T-10.

Most all parts are available for the Avanti transmissions through specialty suppliers, Stephen says, and there is nothing mysterious about the Studebaker automatic.

“Just about any transmission shop can rebuild them if they do old transmissions at all,” he says.

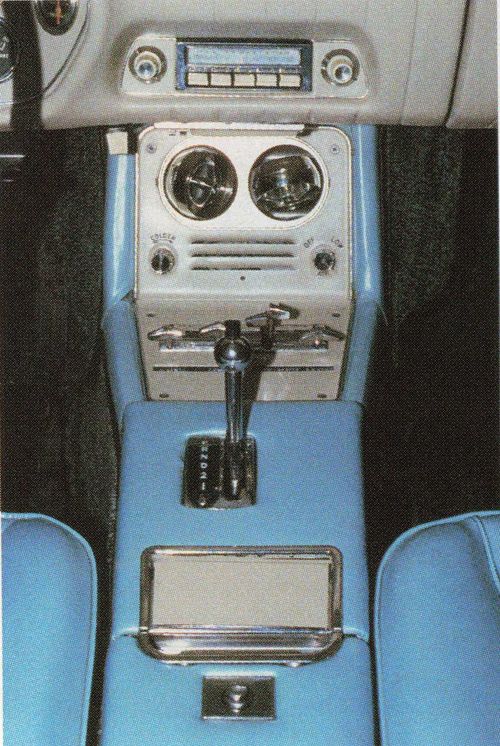

The Flight-O-Matic featured a transmission cooler, an uncommon feature designed for performance driving.

“All Avanti automatics had cooling lines,” Stephen says.

The Warner T-10 four-speed is a well-known gearbox offered in a number of GM cars of the era.

While the three-speed floor shift was theoretically available and is shown in the Avanti parts catalog, a three-speed-equipped Avanti would have to be considered very rare indeed, Stephen says.

Studebaker differentials seldom need much attention, the Cades say. The long-legged 3.31 Twin Traction limited-slip differential seems to be a solid, reliable unit. A good cleaning and new oil was all this one required after 100,000-plus miles.

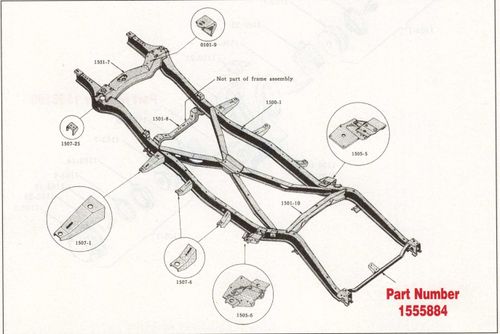

Chassis Inspection

Studebaker borrowed the Avanti frame from the Lark convertible. The rear end was chopped-off behind the leaf spring mounts to produce the short rear deck. This unit was plenty strong enough for the Avanti, but any car that’s 30-plus years old can develop rust problems in the frame.

When checking out an Avanti, pay special attention to the “hog trough” body reinforcement members under the center section of the car. Also examine the rear frame assembly behind the axle and the tubular steel member that runs from side to side just under the rear of the car. The tubular piece commonly rusts. Stephen says a replacement part costs about $100 and can be installed without removing the body, as can the hog troughs.

Where the front suspension A-arms connect to the frame, look for stress cracks in the frame. Such cracks can be repaired by a knowledgeable frame welder, but should never be ignored. Also, if the A-arm bolts have been removed, they tend to work loose again. Use Locktite on the threads to avoid this problem, Stephen says.

Be cautious when working on Avanti disc brakes, because they frequently are improperly rebuilt.

“Better than half of them I’ve taken apart have been put together wrong,” He says.

A critical part of rebuilding Avanti disc brakes is proper placement of a shim — called “front brake caliper lining plate” (part number 1558180 in the Avanti Chassis and Body Parts Catalog) — that properly aligns the caliper with the rotors.

If the plate is damaged or not properly installed, it can move and cut into the rotor. Cade says he’s seen rotors cut nearly in two this way, and there’s not necessarily a lot of warning noise, he says.

“You want to be really careful doing a brake job, or you'll lose your brakes,” he says. “I know that from experience.”

Another critical part on the disc brake assembly is the brake-caliper cylinder jumper line (part #1558068 right, #1558069 left). If this short brake line protrudes too far or if the wrong wheels are used with disc brakes, the wheel can break the line.

“If you want to work on Studebaker brakes, have a parts manual and a shop manual and don’t get in a hurry,” he says.

He also recommends taking the car for a short test drive after doing a brake job and then pulling the wheels off to inspect everything again to make sure there are no problems.

A Studebaker brake job can be expensive, as much as $1500, if you have to replace all the major hydraulic components rather than using rebuild kits.

Rebuild kits are inexpensive, he says — wheel cylinder kits are about $9, and caliper kits about $20 per side. These are typical prices among the major Studebaker parts dealers, he says.

For restorers who don’t feel up to working on the Studebaker system themselves, there are options. Dave Thiebault, a Studebaker specialist in Massachusetts, offers complete, ready-to-install, stainless-steel-sleeved caliper assemblies for about $325 per pair. For restorers who aren’t concerned with brake system originality, Indiana brake specialist Jim Turner offers a hardware kit for about $230 that allows conversion of the Studebaker system to later model GM and Ford parts.

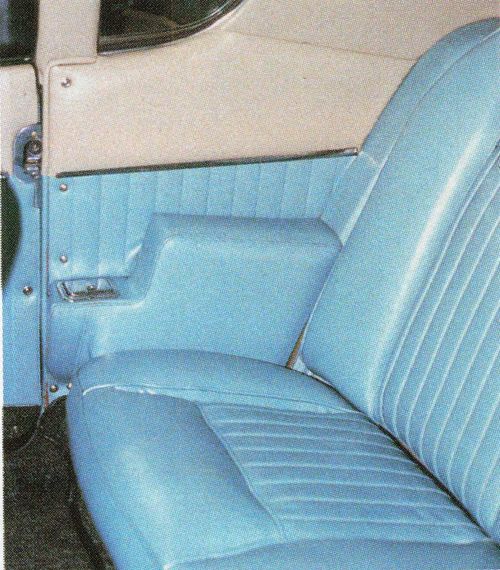

Interior Decorating

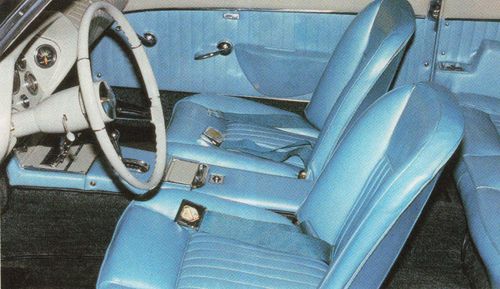

Avanti interiors came in vinyls that matched or complemented the exterior color. Many cars from the last year of production have all-black interiors. The interiors are done in rolled-and pleated patterns, easy for a good upholstery shop to duplicate. The original-type fabrics, colors and patterns are still available from a number of suppliers.

As with most vintage cars, the odd bits of interior and exterior trim can be the most difficult pieces to locate, so shop for a car that has nothing missing.

The interior in the subject car is the one that came in the car though the Cades had it re-dyed during restoration.

When considering an Avanti’s interior, the presence or lack of air conditioning is well worth pondering. Basically, it boils down to a choice between summer comfort and supercharged performance. Air conditioning was an option on unblown R1 Avantis only, like the subject car. Stephen says it might be possible to install air conditioning on a supercharged Avanti, but he’s never tried to do it.

“I don’t think it would be worth the hassle,” he says. “If it’s too hot, drive something else.”

Driving a 1963 Avanti

One of the first things | notice on settling into Robert Cade’s favorite Avanti is that the driver's seat feels much better than appearances suggest. The cushion looks flat and low by modern standards, but after a few minutes | grow accustomed to the setup and no longer notice it.

Directly ahead of the driver is an eight-instrument analog cluster — a large tachometer and 140mph speedometer in the center flanked by amp meter, water temperature gauge and clock on the left, and oil pressure, fuel gauge and vacuum gauge on the right. The instrument cowling drops sharply off to a simple, padded and pleated dash on the right that holds a big glove box and a radio. An aircraft-style panel overhead contains light switches. An upholstered center console contains the air conditioning and heater controls and the transmission gear selector, a chrome lever topped by a round knob and a reverse lockout button.

| punch the throttle with the selector in D, and the Avanti steams off in second gear. It’s rapid enough and sounds good, but is not especially dramatic. | try another start, this time holding the selector in firsthand shifting manually, and the car’s character changes dramatically. The Ri engine emits a gratifying induction moan and launches the Avanti down the road with grin-inducing gusto, while the Twin ~

Traction limited-slip differential assures proper grip. It's great fun. Studebaker was coy about Avanti power ratings, but Studebaker experts reckon the standard R1 engine at 240 plus horsepower. It’s plenty quick.

I stand on the brakes, just short of lockup, and the Avanti stops quickly and under good control. Then we're off again, sweeping through a wide radius curve. Here, the Avanti begins to feel a bit more like the 1960s design it is. It seems a bit front-end heavy and wants to wander wide unless | keep an especially firm hand on the big steering wheel. This feeling is probably due in part to the fact that | am not used to the relatively high effort required by the quick-ratio, 16:1 manual steering this car sports and in part to Its original-style bias-ply tires.

I nudge the speed limit only a little on a deserted Florida backroad and soak up the sights, sounds and feel of a car I’ve wanted to drive since I was 13 years old.