Readers’ Tips—

More On Those Crumbling Brake Shoes

This is regarding the November Mechanic on Duty item “My Brake Shoes Crumbled.” I believe you missed one important clue to Richard Miazga’s brake problem. (Editor’s note: The owner of a 1950 Ford F1 pickup truck was experiencing braking problems and when he pulled his wheels, the brake linings tumbled out in chunks.)

It is true that cheap brake linings can crumble, break up and cause the brakes to drag and stick, but the fact that the brake lights kept sticking on indicates a deeper problem. I don’t know the ’50 Ford truck brake system exactly, but if it is typical of what Ford produced during that time, I would expect to see an under floor master cylinder and a pressure-activated brake light switch.

The fact that Mr. Miazga was having problems with the brake lights sticking on and the brakes dragging would indicate a pressure buildup in the brake system. This buildup most likely caused the shoes to heat up over a period of time and crumble from excessive temperatures.

What Caused That Buildup?

The key here is to find out why the brake system had a pressure buildup to begin with. This is referred to as “residual pressure” and should not build up excessively in the hydraulic system.

Not only must the brake fluid return to the reservoir after a brake application, it also has a high expansion rate as it heats up. The fluid needs a straight route back to the reservoir any time the pedal is not depressed.

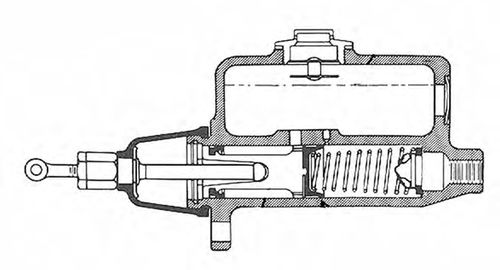

Older drum brake master cylinders, more likely ones that have a low-mounted master cylinder, often have residual pressure valves. (See Figure 1.) These are usually mounted behind the brake line seat in the master cylinder outlet port. These valves should only hold a few pounds of pressure in the system (about 6-10 psi), just enough to keep the wheel cylinder cups from losing their seal but not enough to ever cause the brake lights to come on.

It is also very important that the master cylinder’s pistons fully return to the stop. Master cylinders have a very small port called a “compensator port”(Figure2).This port is located just ahead of the pressure sealing cup and allows an opening to the hydraulic system so that fluid can return to the reservoir. The slightest forward movement of the master cylinder piston will cover this port and seal off the system.

In the case of a brake pedal rider,sticking pedal or misadjusted pedal free play, covering of the compensator port will cause a slow buildup of pressure in the hydraulic system. In turn, this will selfengage the shoes and cause a drag and eventual shoe damage.

Make These Inspections

The things to check would be as follows: Free movement of the brake pedal at its pivot. Any drag here can worsen as things heat up and cause it to stick.

Properly adjusted pedal free play. Every vehicle has a specification for this. Most often it’s around 1/64–1/8”.

Before free play can be properly adjusted, you must make sure the master cylinder piston is fully returning. It is quite common for master cylinder pistons to stick for various reasons. These include but are not limited to, a rusty or corroded bore, old hard seals, debris or buildup in the cylinder, an out of round or damaged cylinder, or damaged pistons.

Debris in the brake fluid can also ultimately clog the compensator port. This can come from old brake fluid or seal material that floats around in the system.

Finally, a defective residual pressure valve can cause fluid pressure to build up to a destructive rate.

The key here is to narrow down what is causing the pressure buildup. It can only be on the master cylinder end, as a seized wheel cylinder would not cause the light to stay on.

Mike Evangelo

ASE Certified Master Tech

Cincinnati, Ohio