Tips for making homemade gaskets

Question:

I’m having trouble finding gaskets and seals for my 1949 Nash Statesman. I’ve tried the usual sources, but they don’t carry all of them. Is there an easy way to make my own, and if so, what do I need?

Answer:

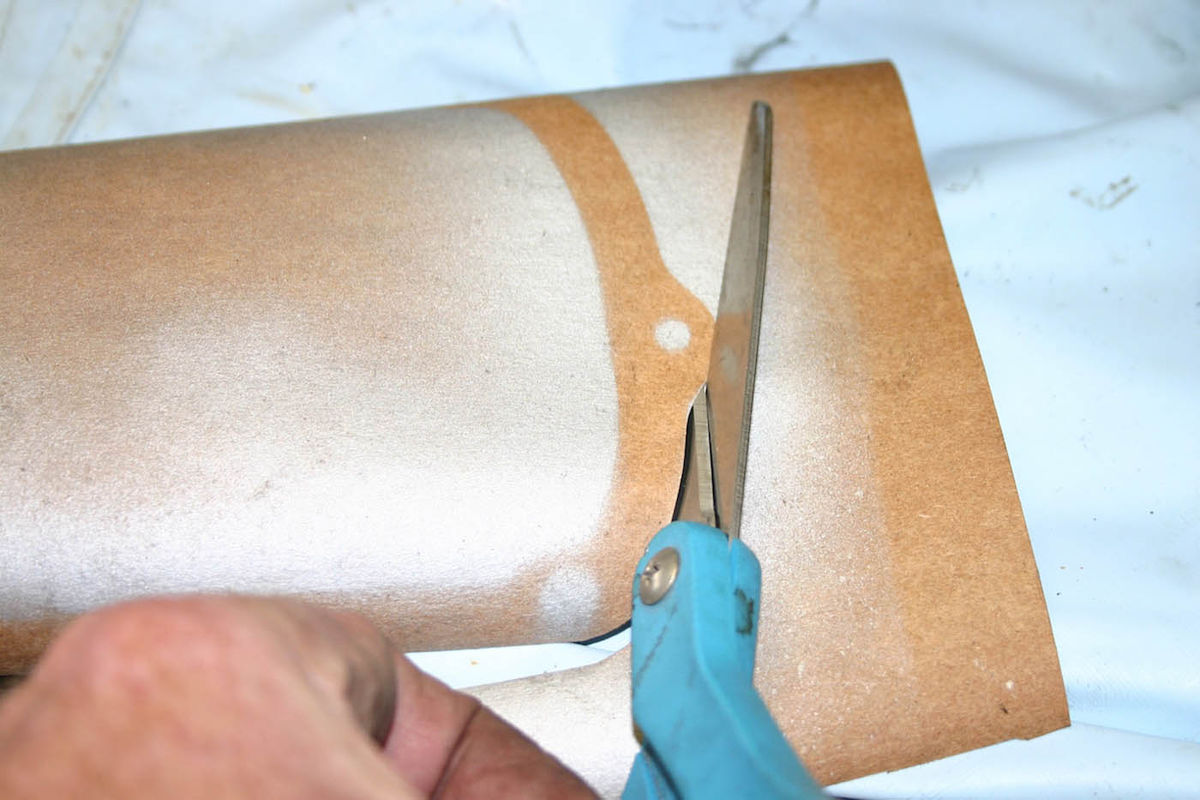

Most auto parts stores sell fiber gasket paper, sheet cork and rubber to make gaskets. One way to get the pattern for a new gasket is to place the old one on a new sheet of gasket paper and fog a little rattle can paint over it. Let it dry, and then you can cut out your new gasket with scissors. Use hole punches or even sharpened tubing to cut the bolt holes.

If you don’t have an intact gasket, you can lay the gasket paper over the part and then tap around it with a ball peen hammer to get the outline. You can even cut the holes that way too, when working on heavy castings. Hold the paper in place and then carefully cut them out by tapping several times until the paper separates.

Just make sure you use the correct thickness of gasket paper for your application. If the paper is too thick, the part you are tightening into place may warp, causing the gasket to leak. And if the paper is too thin, the gasket will not absorb small tolerance differences and leak as well.

Cork gaskets need a little more care, but are still easy to make. Use a utility knife with a fresh blade, and make several light gentle passes to cut out the gasket, so you won’t deform it while cutting. Again, hole punches are the way to cut out the holes.

Rubber gaskets can be made the same way. But don’t over-tighten cork or rubber gaskets because they will just squeeze out like pizza dough and not seal at all.

Another important hint when tightening tin side plates and valve covers into place is to make sure that their mating surfaces are flat before installing them. Such components often deform around the holes where they are attached. Place the part on a flat surface and then tap the flanges flat using a small hammer.

As for sealants, I am old school to the bone. I use either Permatex or Gasgacinch, not silicone, which is a form of engine cholesterol in my opinion, because it can get loose and clog oil passages in the engine.