Oil pressure problems

Question:

I have an 2004 GTO LS motor that has lost oil pressure. At warm idle I now have 15 lbs. psi rather than around 40 psi. I replaced the oil pump with no improvement.

Some folks have suggested that the aluminum LS engines are prone to having the cam bearings spin or shift in the block. I have not been able to find any support for this assertion. Have you heard of or do you know of any cases of this happening?

Answer:

As you are no doubt aware there are a number of things that can cause low oil pressure in an engine, but it is also true that some of the LS1 engines have a problem with cam bearings walking in their journals. You did not mention how many miles are on your engine and whether it has been overhauled at some point, but low oil pressure is a serious problem in any case. Engines self-destruct rather quickly under those circumstances.

Start by making sure you really do have an oil pressure problem by checking to see if the oil pressure sending unit is functioning properly. You can obtain a mechanical oil pressure gauge at an auto parts store or speed shop. Hook it up in place of the sending unit, start the engine and verify the pressure. Sending unit malfunction is common enough that some mechanics just replace the unit first to see if that is the problem.

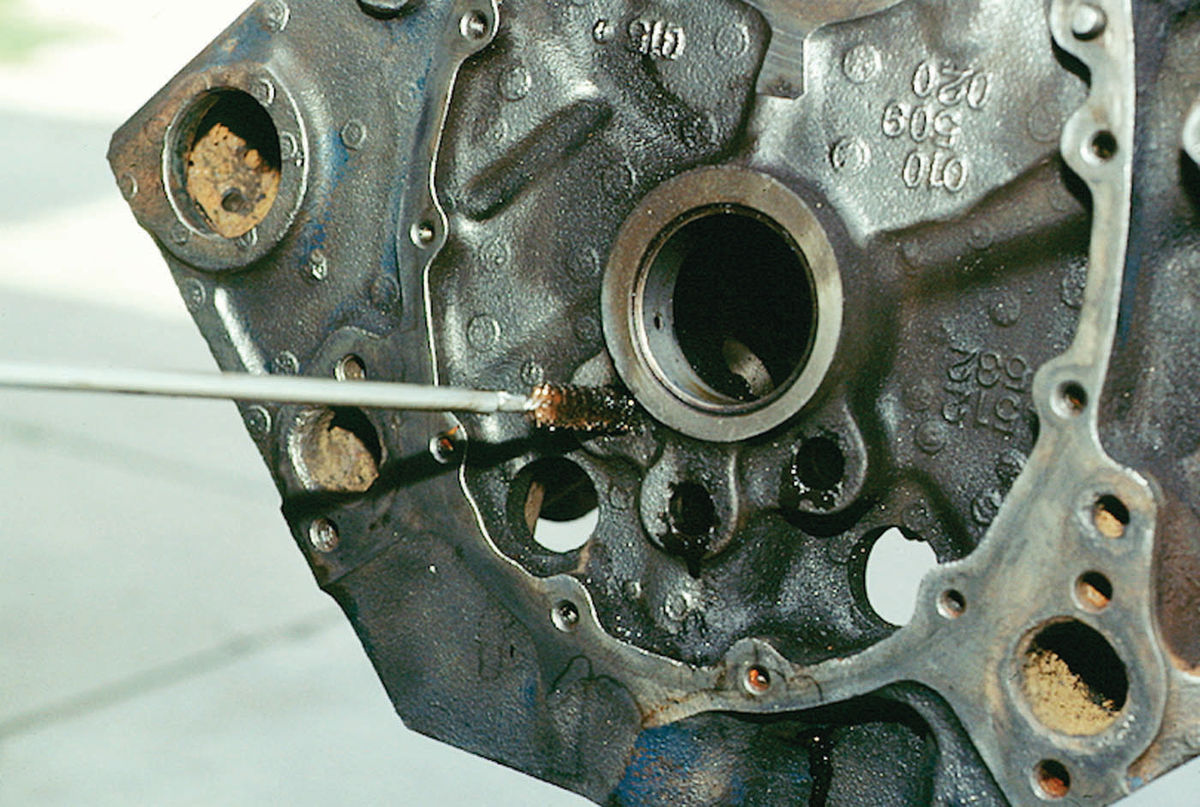

Assuming the pressure is actually low, you can check the cam bearings without removing the engine by removing the intake manifold. You will be able to see the cam and its bearings underneath. If the bearings are walking out of their journals, it will most likely be apparent. You can also check the endplay on the cam by moving it back and forth with a big screwdriver. If it is sloppy, that can be a problem too.

One common reason for cam bearing problems is that when the engine is overhauled, the builder either doesn’t bother to check the clearances on the bearings, or gets them mixed up and puts them into the wrong journals. The number one and number five cam bearings are the same part number on those engines, but number three is unique, being the smallest in outer diameter, and two and four are about .008” larger than it is. And then numbers one and five are about another .008” larger than two and four.

Also, each half of the bearing shell has an oil hole, but only one lines up with the oil gallery that feeds the cam. This can be a bit confusing, but it is crucial that the one hole lines up properly. Use machinist’s micrometers and calipers to carefully verify all clearances. Clean the bearing pillows and the backs of the shells with a rag and lacquer thinner before installing the bearing shells, and then smear grease or cam lube on the bearing surfaces. Finally, carefully check the endplay before attaching the timing chain.

The bearings I prefer are the Durabond Teflon-coated types. You can obtain these from Texas Speed and Performance, if not locally. Just be sure to specify which year and engine you are working on because the bearings vary from year to year. You can reach them at:

Texas Speed and Performance 1621 Aviation Drive Suite 105 Georgetown, TX 78628 www.texas-speed.com

There are other causes of low oil pressure too. Normal engine wear will cause a lowering of oil pressure as time goes by. In fact, the most common cause of pressure loss is engine wear. And that can be hastened considerably by neglect.

If the oil and oil filter weren’t changed often enough, over time the oil galleries will become clogged and restrict the flow of oil to the bearings; and dirty oil can also cause bearing wear which opens up bearing clearances to the point where they will not hold oil pressure any longer. It does not take much wear to make this happen. A couple of thousandths’ bigger clearance is all it takes and the pressure will not hold.

Changing the oil pump will not help either because the oil pump does not actually create pressure; it only creates flow. A more powerful pump will up the pressure a little, but won’t solve the fundamental problem. The orifices and bearings through which the oil flows create the pressure, and if they become larger, the pressure drops. And if that is the case, the prognosis is not good. The only way to fix the situation is to disassemble the engine, check everything for wear using machinist’s tools, and machine the crankshaft and other components to the proper tolerances before replacing the bearings.

Another situation that can cause low oil pressure is a clogged pick-up basket on the pipe going up to the pump. This will restrict flow, as will having the basket in the wrong position in the pan. If the pan has been down, it is possible that the pick-up basket is knocked askew.