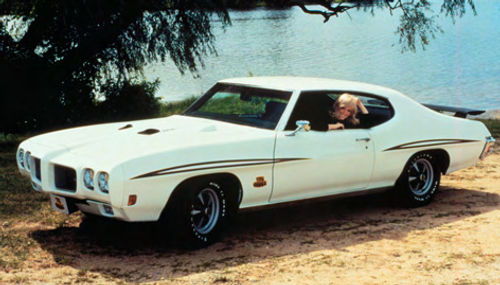

About That “Boiling” GTO & the Bogging Mopar

We Heard About a GTO That Spills Water and a Truck That Bogs. Readers Quickly Shared Their Advice on Both.

EDITOR’S NOTE: IN the January issue we ran a letter from a reader who said his quick GTO runs hot. He recently had the engine rebuilt for his 1969 GTO convertible and reported that the car “runs great and is superfast. I am totally happy with the rebuild and love driving with the new engine.” But on the way home from the engine shop, the radiator “was boiling over and spilling water all over the ground.”However, a temperature gauge said the engine was not excessively hot, and water was circulating in the radiator.Now he’s running the car with the radiator less than full and keeping an eye on the temperature gauge…all the while concerned that his muscle car engine might overheat at any time.

After the letter ran, other Auto Restorer readers responded with their experiences with similar situations and advice on how to fix the problem. We’ll share some of their insights here.

Meanwhile, another letter in the January issue was from a reader whose friend was having trouble with a pickup equipped with a Mopar 318 with throttle body fuel injection. The pickup ran fine at idle but had a mid-range bog. The reader said he couldn’t help his friend because he“didn’t follow the throttle body fuel injection movement” and still likes “the old carburetors.”

In response to that letter, we heard from Mike Foss, Assistant Professor/Co-Coordinator, Automotive Service Technology at the College of DuPage in Glen Ellyn, Illinois. Mike has contributed to these pages in the past and his latest message is on the next page.

Regarding That GTO That Spills Its Water

This is in response to the Mechanic On Duty letter in the January issue. My friend owns a 1967 GTO and historically the car ran hot. Various remedies were tried short of an all-out rebuild to pursue the possibility of clogged water passages. The owner had purchased it used and verified it had always had an overheating problem. Mechanics had given up and said it needed a rebuild.

So in early 2002 the GTO went under the restoration process and the engine was rebuilt. We carefully mapped and diagramed out where things went. Once completed, we started it up only to find out it was still running hot. You can imagine the displeasure arising from the idea the engine had been professionally rebuilt and was still overheating. Again we went through it and found nothing to cause the problem.

After almost giving up on the engine and opting to do something else, I called an engine rebuild shop near where I live and explained it to one of the men there. His first question: How do we have this one hose hooked up? I replied I don’t know; I would have to look. Then it was like finding a pot of gold.

Apparently since the car was purchased used and prior to the current owners knowledge, someone had rerouted the back right heater hose the same way it would work on a Chevrolet small block. Pontiac engines, come to find out, are not that way. So we researched the Pontiac Manual and we found the problem. Rerouting the hoses to the Pontiac way resolved the overheating problem instantly. I reported back to the shop that the problem was solved and they advised that this is a very common mistake made thinking that components on Pontiacs and Chevrolets were the same since they were both “GM.”

I hope this will answer Sam Toll’s problem. After reading his letter it seems as though we could have written it nine years ago.

Charlie Dolan Via email

Regarding the GTO that runs hot. I’m not a professional mechanic but I’ve messed with cars for 50+ years. I road raced a Camaro a few years ago and I’m more familiar with Chevrolet Small block engines but I’ve built others.

I own a 1980 Pontiac Grand LeMans that I purchased new. It had a Pontiac 265 cid engine but I had to replace it a few years ago after I found part of a main bearing saddle had broken off when I had it down to rebuild.I replaced it with a 30-over 301.

The car wasn’t equipped with a temperature gauge so I added one. I don’t recall if I had detected an overheating problem before the gauge was added but at some point, there was an indication of overheating. I replaced the water pump more than once, the clutch fan more than once using different designs, the cap using stock and higher temperature ratings, the thermostat with the standard 195-degree and later to a 180- and a 160- degree, and I replaced the 2-tube radiator with a 4-tube unit.

I considered restricted air flow through the radiator and the possibility of the air dam under the car flexing. It still didn’t like traffic in hot weather. The problem continued after I built the 301.

I tried something that I had discovered while trying to solve an overheating problem with an old fire engine. I also had applied the same tactic on a race engine.After filling the cooling system, I ran the engine with the radiator cap off to allow air bubbles to be purged. I had assumed the bubbles would have been purged during normal operation. This along with a 160- or 180-degree thermostat seemed to “correct” the problem. However, temperatures in cold weather may be too cool.

Here’s a couple more thoughts.

I would check the temperature gauge for accuracy. I found a mechanical gauge that read several degrees high. On my Pontiac, I fabricated an adapter so I could install the sending unit at the top inlet to the radiator.

The article mentions the fluid level was circulating at the 3/4-full level. When I ran my engine with the cap off, the flowing liquid was below the top of the radiator and above the tubes. Should his liquid level be “3/4”?

I wonder about the color of the antifreeze mix too. If the engine and heads were hot-tanked, the discoloration must be coming from the radiator. I’ve tried more than once to have radiators repaired and/or hot-tanked. For several years I’ve purchased new radiators from NAPA. Shoot, they have a lifetime warranty so why not go with a new one.

One thing I learned while building the Pontiac 301; the engine side of the cooling system isn’t like a Chevrolet.

Great magazine.

A. W. (Ossie) DeLay, Jr. Via email

Concerning the hot GTO in the January issue, Pontiac water pumps use a backing plate that controls and directs coolant flow. The plate does not come with a new water pump. My money says the engine builder didn’t install the plate on the backside of the pump.

Dave Moll Via email

I have a couple of ideas on the hot running GTO in the January issue.

First off, I am confused about his saying that the radiator should be 3/4 full? If he starts off that low, it is possible that there is no water touching the temperature sending unit. Many of them only record the temperature if they are immersed in water. They can’t sense the temperature of the metal they are screwed into.

To me, the correct height of the water when the engine was hot would be just an inch or so below the radiator cap.

If the car is really running at 210 or less and it is blowing water out the radiator, that could be caused by a leaking head gasket or a cracked head letting combustion gases into the water and building up pressure. One way to check that is to warm up the engine with the radiator cap off. Then stop the engine and remove all belts that drive the water pump. Start the engine and observe the water in the radiator. It should be still, other than some motion from the vibration of the engine. Have someone hold the brakes and put a load on the engine. If you see bubbles, it confirms a combustion gas leak.

Alex Magdaleno Camarillo, California

More On That Problem With Throttle body Fuel Injection

This is Mike Foss again, automotive instructor at College of DuPage, with a reply to a Mechanic On Duty question from a reader. I finally finished the January issue (another great issue, I might add) and would like to respond to Paul Zuhosky's question. What set me off was the title, “This problem’s too modern for me.” I have a fear that the hobby is in trouble. The newer cars will not be restored because they are not as simple as the early models were. With some education, not much, these cars are not that bad to figure out.

My humble opinion on this Dodge Pickup is as follows:

Not to pick on Paul but I wish he would have supplied the year, make and model with the transmission type…as a college instructor I beat my students up on this every day in class…don’t even ask the question unless you have the year, make, model, engine size and transmission type! Some of what I am going to try to explain is going to be guessing because of the lack of the vital information. I will make a stab at it anyway.

Auto Restorer was correct in saying there is a vacuum leak on the late-model Dodge Pickup. The issue that Paul may run into (I know I certainly have over the years with this type of Mopar) is a vacuum leak that is next to impossible to find unless the restorer is educated. In my opinion, the issue with this Dodge is an Exhaust Gas Recirculation (EGR) valve is opening too much and prematurely, causing the bog that Paul is complaining about.

The early Mopars used an EGR system that used 2-3 components, the valve (no kidding), a BACK PRESSURE TRANSDUCER (the culprit in my opinion), depending on the year (which I don’t have) an electric solenoid that is computer-controlled and, of course, vacuum lines to hook everything up. I might add that the system is so simple (systems without the solenoid), the folks at Mopar did not feel it needed a diagnostic code. These systems can fail and not turn on the “check engine”light or “power loss”light.

But before we get too far, let’s cover some basics. First, the fuel injection. The Throttle body Injection (TBI) system was a stopgap measure to provide Electronic Fuel Injection (EFI) to the market. Why EFI? Better fuel mileage, better drivability, and less pollution (emissions).

The TBI EFI system is the simplest system of fuel injection to understand because it mimics a carburetor in looks. Because of this fact it is the ideal fit for the older restorer. The issue becomes the mind block, “it’s electronic; I cannot figure it out,” that we need to overcome. When it comes to Mopar and GM these were one of the more reliable fuel injection systems out there (not very sophisticated). Ford did use this system but it only lasted a few years and for guys like me that had to fix them everyday…they were not very reliable and not technician friendly. The Mopar system was superior to GM because the diagnostics for the computer systems were better. There were more codes but more descriptive codes making it easier to find and fix a computer problem quicker but not necessarily a drivability problem.

Now the EGR system. I can hear the older restorers now, “What the heck do we need this thing for?” We all like better fuel mileage…right?! OK, when we lean out the fuel mixtures on a gasoline- fueled engine to get better fuel mileage the combustion temperatures start to rise. When the temperature in the combustion chamber reaches 2500° F normally stable and unreactive nitrogen in the air becomes unstable and reactive and bonds to free oxygen in the combustion chamber creating Nitrogen Oxides (NOx). The x is for the unknown amount of oxygen atoms that bonded to the nitrogen, could be 1, 2 or 3. NOx and hydrocarbon (gasoline vapors) in direct sunlight creates photochemical smog. Enter the EGR valve about 1972; its purpose is to reduce the combustion temperatures to somewhere below the 2500° F mark thereby reducing NOx. The EGR system takes a small amount of exhaust gas (inert) and introduces it to the intake manifold. The exhaust gas takes up space in the combustion chamber that would be occupied by air and fuel. Because the exhaust gas is inert it does not become part of the combustion process and lowers the combustion temperature. EGR valves are very specific to the year, make, model, engine size, trans- mission type, emission calibration, and other things that I have forgotten. I need to add one more fact related to exhaust gases that I am sure everybody knows but I want to be sure…part of the normal combustion process is the development of H2O.

Now, the issue on the Dodge. The back pressure transducer is a black plastic, pancake-looking thing with three vacuum hoses going to it. The transducer is there to control the AMOUNT and WHEN the EGR opens. I want everybody to understand why this component fails…it’s the educator in me. The transducer has one hose connected to the TBI unit; this is the carburetor-looking thing on the manifold, that is most likely a ported vacuum source. Ported vacuum is only present when the throttle is opened up…no vacuum at idle. The next vacuum line runs from the transducer and is connected to the EGR valve, when vacuum is applied to the valve it will open up a passage between the intake and exhaust manifolds. The last hose is not vacuum…it is connected to the exhaust system and its job is to supply exhaust back pressure to a diaphragm inside the transducer. Now let’s look inside the transducer. There is a rubber diaphragm with a metal spring...pretty simple. You can take this component apart, the two halves unsnap, watch the spring if there is one left. Now let’s think about this for a minute. Rubber and metal exposed to exhaust gases. So what happens, in most of the cases I have seen, the H2O in the exhaust rusts the spring and the spring loses tension. Now the slightest amount of back pressure opens up the EGR valve…from what I have seen WIDE OPEN. This will cause the EGR valve to open prematurely and wide open thereby causing a bog on acceleration. It’s what I call an internal vacuum leak.

Now that we understand the system and what goes wrong let’s diagnose it. It is real simple…disconnect the transducer and plug the vacuum line. Take the truck for a ride…is the bog gone?

1. Yes, great…remember the truck is STILL BROKEN…go to the auto parts store and purchase a new EGR valve which will come with the transducer. You will need the part number that is on the old EGR valve. If it is missing it can be gotten without the factory number but it is easier if you have it. Before leaving the auto parts store open up the box and make sure the transducer is in the box…some part suppliers do not supply the transducer…it is worthless without it! Some people would say why bother replacing the EGR valve. Well, remember the exhaust gas from the properly operating EGR valve is occupying “space” in the combustion chamber; that “space” will otherwise be occupied by fuel and air so the fuel mileage on this truck will suffer (not that it is that great on fuel now but it will be worse).

2. If the bog is still there, I am truly sorry for wasting your time.

I would like to add one more thing to the pile for those of you that like to modify exhaust systems by reducing the amount of back pressure. There are a lot of EGR systems that rely on exhaust back pressure to meter the amount of EGR introduced to the intake. In most systems the lower the back pressure the less EGR introduced. So the most common complaint I get is, “I put dual glass packs on my truck and my fuel mileage went down and my power is great.” If this does not make sense to you…read it ALL again!

Keep up the great work on the magazine!

Mike Foss College of DuPage Glen Ellyn, Illinois

Editor’s note: DuPage says its Automotive Service Technology program “is intended to provide education and practice in automotive system operation, diagnosis, and repair of passenger cars, SUVs and light trucks. Certificate and associate degree programs are available to students to help prepare them to enter the workforce or transfer to a 4-year institution to complete a bachelor’s degree.” The school is located west of Chicago. For more information, visit cod.edu.